Product description:

HANS GS Laser Perforating Machine MICROPOROUS / MACROPOROUS PERFORATION SYSTEM OF CIGARETTE TIPPING PAPER

HANS GS Laser Perforating Machines are widely used in the tobacco packaging industry, mainly to perforate holes on the cigarette tipping paper to increase the air permeability of the paper and reduce the tar and nicotine.

The system can be applied to the plastic film packaging industry, which can maximize the shelf life of fresh food or easy open packaging by laser perforation on the film.

General performance of HANS*GS-D400P laser perforating machine

Laser power | 450W/650W/1000W |

PLC control type | closed-loop |

Controller | Germany servo system |

Form feeding control | Biaxial linkage control |

Indicator setting method | Independent, simple |

Spectrophotometric method | by polygon prism |

Permeability range | 100-2000cu |

Permeability instability | Less than 5% (relative error) |

Maximum peforating speed | 1920 thousand /min |

Maximum punching density | 4pcs/mm |

Minimum punching density | 1pc/10mm |

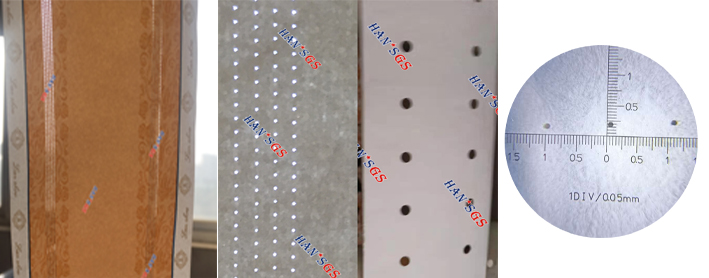

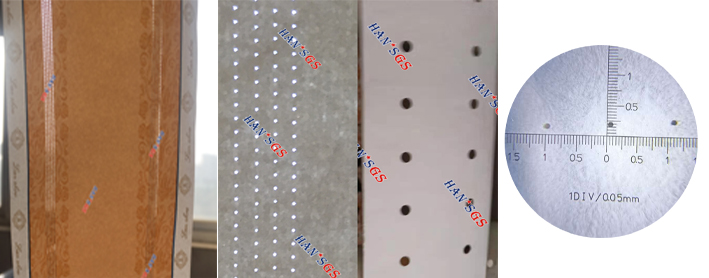

Hole diameter range | 0.05-0.25 mm |

Hole shape | Oval, round, strip ,various shapes (customized products) |

Hole quality | neat, without deckle edge or coking |

Maximum feeding speed | 650m/ min |

Perforating rows | 1-8 rows |

Acceleration time (0-300m/min) | 3sec |

Total system power | 35KW |

Width range of processing tipping paper tray | 40-80mm |

Maximum processing winding tray diameter | 520mm |

Unperforated length at the beginning and end | 15M(front),2M(tail) |

Environment requirement | 20-30ºC Constant temperature |

Machine lifetime | 10 years |

Chilling water hardness | 250mg/L |

Gas consumption of laser head | 2.8L/min |

Temperature of cooling machine, adjusting range | 10-30ºC |

About the cooling machine temperature and adjusting precision, is there monitor display | ±0.1ºC |

Chilling water flow speed | 25L/MIN |

Water storage capacity of chiller | 0.3M3 |

HANS GS Perforating machine of cigarette tipping paper advantages:

I. Perforation air permeablity from 100CU to 2000CU. Perforation speed up to 650m/min!

II. Standard perforation 1~4 rows each side. perforation rows can be selected.

III. Multiple shapes of hole,such as oval / round / strip hole / Various hole shapes.

IV. Stable performance, up to seven years of trouble free operation.

V. Positionable perforating .

Perforating Sample

We offer laser perforation system solutions and can customize perforation products.

Further details call us (0086-27-8792 4929) or mail to: hansgs@hansgslaser.com

Product description:

HANS GS Laser Perforating Machines are widely used in the tobacco packaging industry, mainly to perforate holes on the cigarette tipping paper to increase the air permeability of the paper and reduce the tar and nicotine.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam