Product description:

GS-DKJ02 Laser perforating system for plastic

HAN′S GS always stands in the technology frontier, researching laser perforating technology. GS-DKJ02 Laser perforating machine is integration of laser, mechanical and electric control. The system adopts automatic production including control constant tension force, constant speed plastic delivery, dynamic laser tracking perforating system, speed inspection and laser power control. The high power density laser after focusing effect on the plastic surface to increase the temperature of the beam area to the melting point even boiling point within micro-second time; forming the laser perforating hole. Meantime, the selective layer perforating for plastic is feasible through the adjustment of the laser power.

Main equipment technical indicator

Laser power: | 55W, 100W 200W |

Hole diameter: | ¢0.1-¢0.2m |

Hole length: | plastic wrap length |

Speed: | 0-200m/min |

Row space adjustment range: | 0-20mm |

Hole space adjustment range: | 1-10mm |

Row: | (can be set) |

Area: | 150-550mm |

Horizontal adjustment travel of the shock |

focus: | 300mm |

Vertical adjustment range: | 50mm |

perforating range: | 60mm x 60mm |

Single layer perforating, Bottom layer without hole can be realized during the double layer plastic. |

Core components is optional

Laser Source

Using US brand Coherent laser generator, the laser wave length is 10.6 μm, which belongs to infrared channel. CO2 laser generator has big power and high Electro optic conversion rate, it’s mature and widely used laser generator. CO2 laser source use CO2 gas as working medium, filling CO2 and other auxiliary gas into the discharging tube. The glow discharge will occur in the tube when there’s high voltage electricity affected on the electrode so that the gas molecule release the laser. The laser beam after expansion can be used for laser processing.

Chiller

The chiller is used for the cooling for laser generator to ensure the constant

temperature working environment. We use HC045 air chiller produced by Hans Laser,

the chiller equip with temperature gauge, liquid level, flow alarm. Easy setting and can be used for cooling for two sets of laser generator.

Two dimension adjustment table

1.The two dimension adjustment table is used for the adjustment for the vertical and

horizontal position of the laser source.

2.The horizontal adjustment is for the perforating edge distance.

3.The vertical adjustment is for the focus distance.

4.Adjustment for row space of double or three rows is realized within the

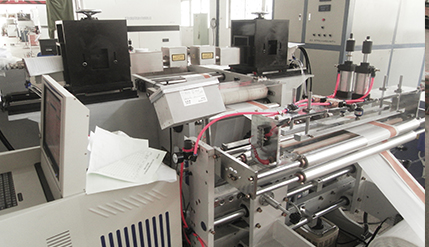

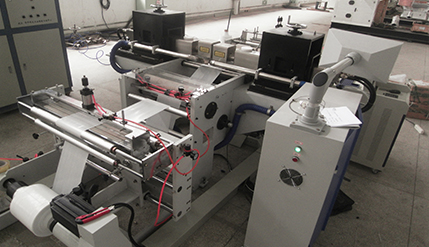

Real photo of the Plastic wrap laser perforating

Product description:

Laser Source Laser Perforating Machine for plastic film , Find Complete Details about Laser Perforating Machine for plastic film, Laser Perforating Machine for plastic film Price,Laser Perforating Machine for plastic film from Other Laser Perforating Machine Supplier or Manufacturer-HANAS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam