Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Address:No.72,Optical valley Avenue, East Lake High-Tech Development Zone,Wuhan.P.C:430223

Tel:+86-27-8792 4929

Fax:+86-27-8792 4929

Whats app:+86-18717170727

Skype:sales_hansgs@outlook.com

Email:hansgs@hansgslaser.com

Product features

The products are widely used in steel industry —— strip rolling, acid pickling, coating, annealing and other fields. Its main function is welding automatically joints in the production of plate strip.

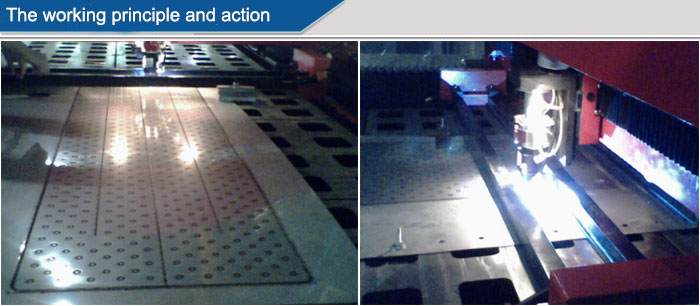

1, Laser cutting system cut automatically the head part and the tail part.

2, Synchronous servo system to complete the lead, with the end of the automatic splicing

3, Laser automatic welding system to complete the dare seam.

4, The two time synchronous servo system is in the middle of the system.

5, Automatic measurement of strip width and thickness.

6, Automatic clamping system to complete the initial positioning of the plate belt.

7, SIEMENS multi axis motion control system using SIMOTION.

8, Fully automatic production equipment for highly integrated optical, mechanical,

electrical, hydraulic, pneumatic and cooling technologies.

9, After welding, the broken belt rate can be guaranteed to be 1/1000.

Specifications

Products for the T type structure, applicable to the board with a width of 1500MM, the host travel 3500MM, the maximum moving speed of 10 m/min, the main operating speed of the machine tool for m/min 0.5-12 adjustable.

Model | GS-BDHJ2000 |

structure | T type |

Board width | 1500 mm |

host travel | 3500 mm |

Maximum moving speed | 10 m/min |

speed of the machine tool | 0.5-12 m/min |

1, Laser welding system Rofin high power laser system and the laser cutting path etc.

2, SIEMENS SIMOTION motion control system.

3, Monitoring system

Product Ad vantage

1.Highly automatic level: adopting auto preheat machine, robotic hand for loading and unloading, four-stations auto turn plate.

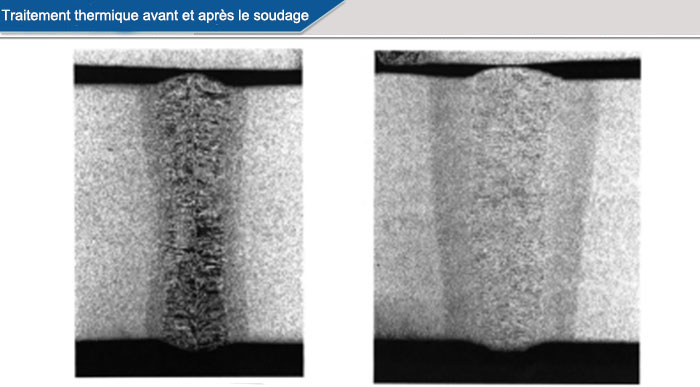

2. High quality: with auto pressing device, effectively reduce welding deformation, highly improve the production efficiency and quality.

3. Highly integration: integrated the auto preheat machine, melding main machine and unloading conveyor together.

4. Without space limitation, could weld small part and the parts of close interval.

5. Non-contact welding, greatly reduce the deformation and wear of the appliance.

6. Can weld various materials, and even any two kinds of various different textures and different natures can be welded well.

Laser welding application

Laser welding is mainly used in automobile, tools, home appliance, steel industry and others, forexample nest gear of transmission, flying wheel, airbag, rock arm, muffler, silicon oil shockabsorber, hydraulic torque converter, wood saw blade, diamond saw blade, radiator of water.

Our service

Technical Support

Guided with our company culture of “Grape market with service" and with the service idea for getting users’ satisfaction as well as customer’s profit, our company set up special technical team for laser heat treatment cladding, welding, cutting, punching appliance with strategic agreement signed with IPG, LASERLINEDILAS Germany, ABB Robot Switzerland, KUKA Robot Switzerland, Material Colleague of Tsinghua University, aviation material institution, material colleague of Wuhan university of science and technology to provide long term technical support for our users.

We’re promised to provide comprehensive technical support for customer and our technique process database.

1) Specified technical train and instruction to ensure master of operation

2) Process and technical instruction for typical work piece to master the basic selection of parameter for the laser processing

3) Laser powder company list for users

4) Comprehensive technique support for new technique development by customer

5) Technique live service.