Product description:

Parameters:

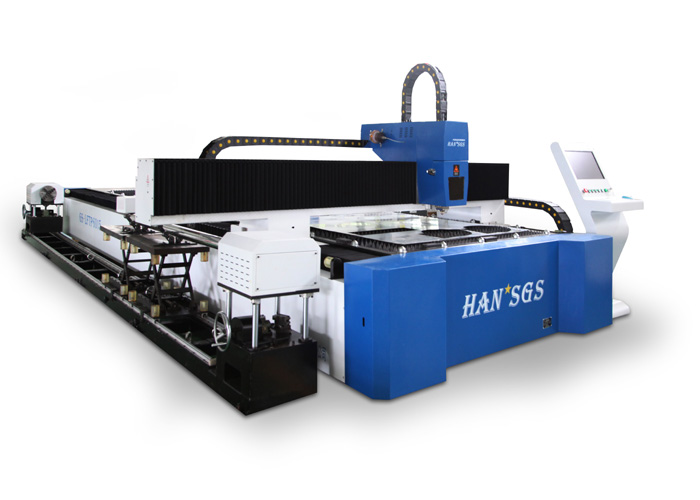

Model | GS-LFTP3015 |

Output power of laser source | 500W/1000W |

Cutting area (L*W) | 3000mm × 1500mm |

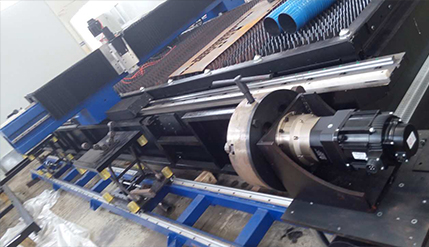

Max tube diameter | 200mm |

Max tube processing length | 3m |

Max tube cutting thickness | 5mm |

X axle stroke | 3048 mm |

Y axle stroke | 2000 mm |

Z axle stroke | 80 mm |

Cooling | water cooling |

Max accelerated speed of X, Y axles | 1G |

Kerf Width | 0.1~0.3 mm |

Positioning accuracy of X, Y and Z axles | ±0.05 mm |

Repeated positioning accuracy of X, Y and Z axles | ±0.03 mm |

Processing precision of work piece | ±0.1 mm |

Kerf harshness | Ra 3.2—12.5 μm |

Voltage | 380V,50/60Hz |

Continuous working time | 24 Hours |

Max bearing weight of working platform | 600Kgs |

Total installed capacity | 20-25 KVA |

Total protection level of power supply | IP54 |

Machine Bed

1.Gantry design with double rack and guide, double drive with servo motor; Integral cast aluminum crossbeam of high performance.

2.Welding type machine frame with manual aging treatment; the machine bed is precision processed by gantry type milling machine to ensure the resistance to shock, rigidity and stability.

3.The crossbeam made of high intensity aluminum has the feature of light weight, high rigidity and good accelerating ability; precise process by gantry type milling machine after aging treatment to ensure the movement precision.

4.The aging treatment during the welding to remove welding stress in order to prevent the structure deformation.

5.HIWIN square linear guide from Taiwan with high position precision, less wear; high precision for long service time, easy installation and replacement.

Application Industry

Widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, tube fittings, automobile, food machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, kitchen utensils and appliances, craft gifts, tool processing, decoration, advertising and other manufacturing industries.

Cutting Sample

After-Sale Service

Our after-sale network is all over the world which will provide the comprehensive after-sale service to our customer.

Our commitment is as follow:

One year guarantee for the whole equipment.

We will answer your questions within 24hours.

When Equipment warranty expires, lifelong maintenance services will be provided.

After the expiry of the warranty we will offer a wide range of software support with free upgrade for lifelong .

Product description:

Sheet & Tube Laser Cutting Machine ,Sheet & Tube Laser Cutting Machine Price,Sheet & Tube Laser Cutting Machine suppliers -HANS GS Laser

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam