Product description:

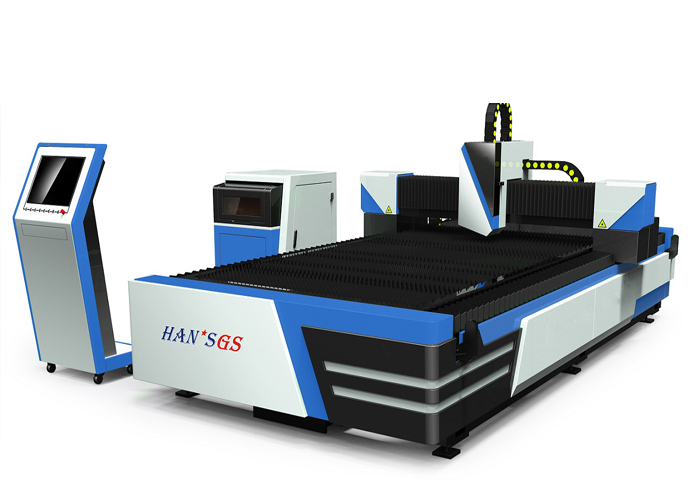

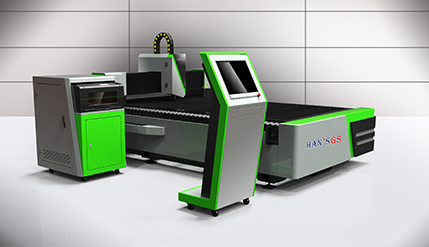

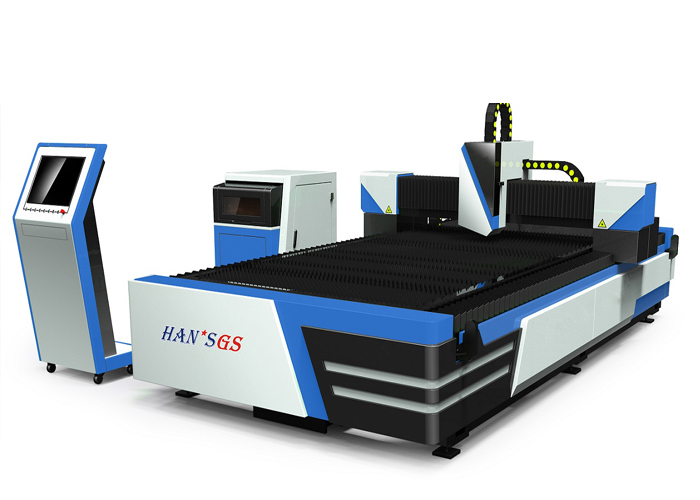

Economic Fiber Laser Cutting Machine GS-LFD3015

Features

1.The machine is used for cutting a variety of metals with excellent and stable cutting quality.

2.Application of gantry structure and High Strength Whole Welding Cutting Bed to achieve higher rigidity, stability, shock resistance.

3.High-performance laser source and stable operating system which make the best cutting effect.

4.The machine with perfect cooling system,automatic lubrication system and dust removal system, to ensure that it can operate stably, efficiently and durably.

5.The professional CNC cutting system and automatic nesting software aim to maximally save raw materials.

6.Access to the CNC system through ethernet interface makes communication and remote monitoring possible during the laser cutting process.

Laser Cutting Machine Parameters

Model | GS-LFD3015 |

Laser source medium | Fiber |

Laser power | 500W~2,000W |

Cutting range(L*W) | 1300*2500/1500*3000/2000*4000/1500*6000/2000*6000mm |

Z axle stroke | 100 mm |

Max positioning speed | 120m/min |

Max height of feeding material | more than 120mm |

Cooling form | water cooling |

Laser wavelength | 1070nm |

Min. cutting gap | ≤0.1mm |

Positioning accuracy of X, Y and Z axles | ±0.03 mm |

Repeated positioning accuracy of X, Y and Z axles | ±0.02 mm |

Thickness of cutting material (according to material) | 0.2-12mm |

Drive model | Imported servo motor |

Power requirement | 240V/380V/400V,50/60Hz |

Working temperature | 5-45 degrees |

Continuous working time | 24 hours |

Machine weight | About 6750Kgs |

Outer dimension | 4270mm x2280mm x 1750mm |

Total protection level of power supply | IP54 |

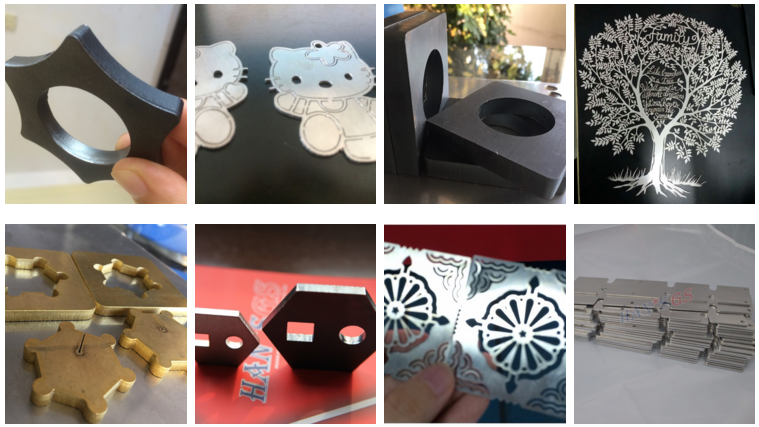

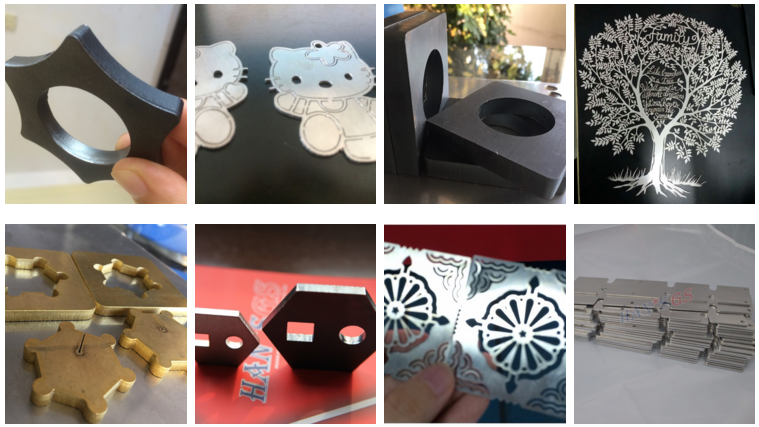

Cutting Samples

Product description:

Quality Metal Laser cutting Machine supplier/manufacturer, buy high quality Metal Laser Cutting Machine , Metal Laser cutting Machine On Sale in HANS GS LASER.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam