Product description:

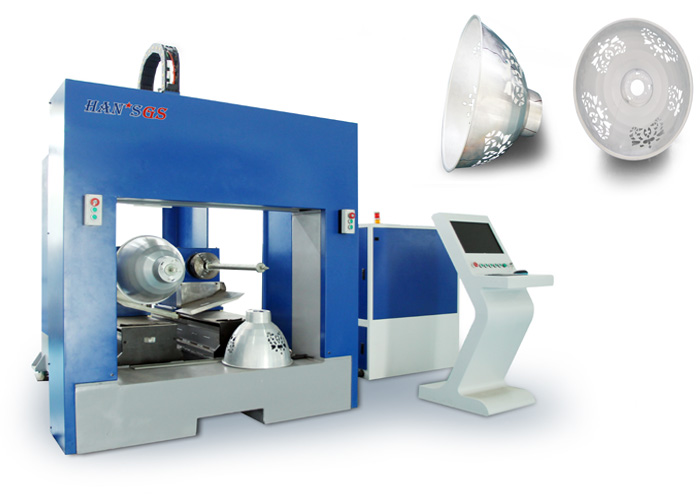

New Design CNC Sheet Metal Lampshade Laser Cutting Machine For Lightings

Product introduction:

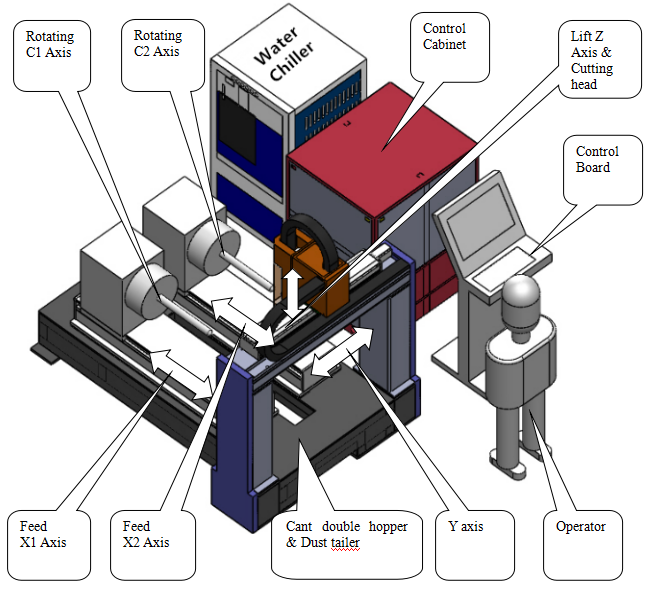

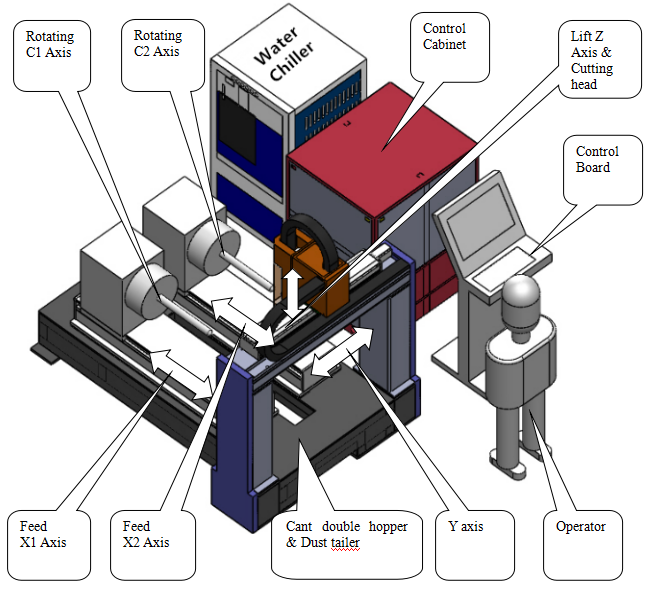

The

cutting machine is the duplex mode, the operator stands as the below

picture shows, X1 axis & X2 axis can be alternately cut and

refueling, which can greatly improve the efficiency. After X1 axis

completed the cutting, workpiece will be transmitted to the operator of

X1 axis, the operator can up & down materials at the same time, then

X2 axis deliver the workpiece to under the cutting head to cut; After

X2 axis completed the cutting, workpiece will be transmitted to the

operator of X2 axis for loading & unloading materials, then X1 axis

deliver the workpiece to under the cutting head to cut, alternate each

other like this. It ensures maximum utilization of the laser, has

remained substantially cut, greatly enhance the cutting efficiency.

Specifications

NO. | ITEM | SPECIFICATIONS |

1 | Machine bed | GS-LFS1010-500 |

2 | Laser source | IPG 500W/700W/1000W |

3 | CNC control system | German Beckhoof |

4 | Operating system | United States AheadTechs |

5 | Z axis servo system | Switzerland RayTools |

6 | Laser cutting head | Switzerland RayTools |

7 | Nesting software | UK radan |

8 | Servo motor and drive | Japan Panasonic AC servo motor and drive |

9 | Precision planetary gear reducer | GPX142 i=25 |

10 | Precision linear guide & screw | HIWIN |

11 | Control cabinet & operation board |

|

12 | Temperature and humidity adjusting machine | 250W |

13 | Cooling system | HC025M |

14 | Voltage Stabilized supply | 20KVA |

15 | Display | 19” (Equipped with wireless mouse) |

16 | Lubrication system | Motion axis lubrication |

17 | Maximum cutting workpiece | φ500X800(Length)mm |

Machine feature

1.With

agreement signed between IPG and Han’s Laser, we’re the strategy

partner of IPG(largest customer in the world). All IPG laser source

delivered to us is restrict inspected by IPG Company, and fast respond

speed from IPG for us if there’s any problem with the laser source.

2.The most progressive capacitance non-contact automatic tracking system, closing link makes signal more stable and responsive.

3

protective function:board touching alarm; cutting material insufficient

alarm;error tracking alarm; edge misplace alarm.It makes laser head

moving trajectory like leaping frog, it is faster compare with

traditional moving trajectory.

Cutting Samples

Product description:

Lampshade Laser Cutting Machine, Find Complete Details about Lampshade Laser Cutting Machine manufacture,Lampshade Laser Cutting Machine Price,Lampshade Laser Cutting Machinet supplier-HANS GS Laser

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam