Product description:

Description:

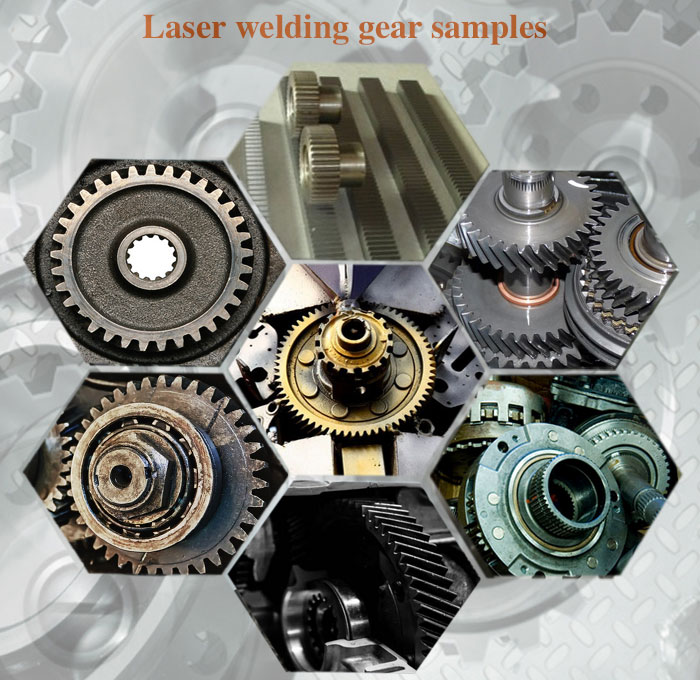

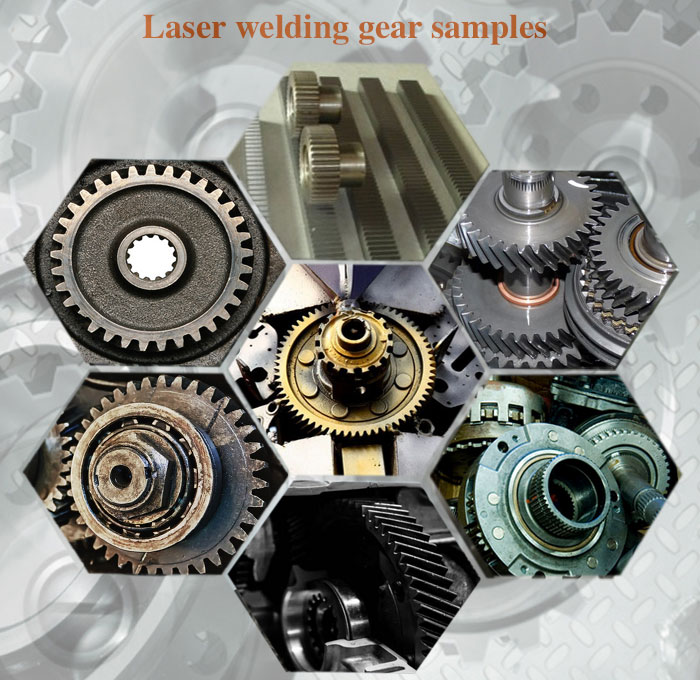

1.The application of laser welding in automobile manufacturing begins in the transmission gear welding, in the design and manufacture of auto transmission gear, in order to reduce the gear's weight, volume and machining difficulty, and to save raw materials, developed countries have processed gears or gear shafts in split-type instead of wholistic machining then weld the two parts together to be an integrated part.

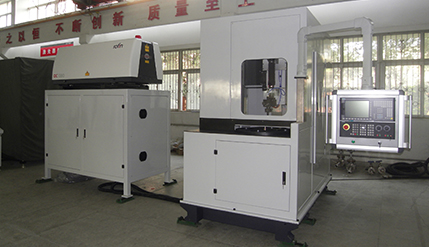

2.HC03 high power gear laser welding machine, is composed by high power Rofin-DC030/DC035 laser source, water chiller, processing machine tool, auto preheat machine, robotic hand for loading and unloading, CNC system and do on. The control system can realize integrated control to the whole machine, such as processing machine tool, water chiller, protective air unit and so on It is easy to adj ust the parameters, with centralized display and strong anti-interference ability. With reasonable hardware and software, durable and stable, protect operator's safety by laser fence.HC03 type welding achine is specialized in processing transmission dual gear, dual gear shaft of automobiles.

Specifications:

Model | GS-HC03 |

Laser source | Rofin-DC030 (fiber/CO2) |

Output wave length | 10.6 um |

Output power range | 300 - 3000W |

Power stability | ±2% (long term) |

Diameter of laser beam | 20 - 25 mm |

Laser beam stability | ≤ 0.15 mrad |

Water chiller | LSJR-500BX chilling system |

rated refrigerating | 50kW |

CNC machine tool (X, Y, Z -axis) |

Location accuracy | ≥±0.02 mm |

Relocation accuracy | ≥±0.01 mm |

4-station and auto loading turn plate | 0.9 s/station |

Processing parameters |

Max. Welding depth | 5 mm |

Min. Welding width | 1 mm |

Welding speed | 1.5 - 3.0 m/min |

Processing size |

External diameter | Φ40 - Φ130 mm |

Internal diameter | Φ35 - Φ70 mm |

Thickness | 20 - 60 mm |

Max. Length of gear shaft | 350 mm |

Max. Diameter of gear shaft location | Φ35 mm |

Control system | SIEMENS 828D+auxiliary PLC |

Product Advantages:

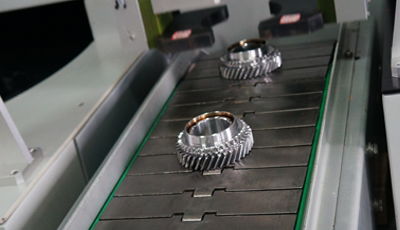

1.Highly automatic level: adopting auto preheat machine, robotic hand for loading and unloading, four-stations auto turn plate.

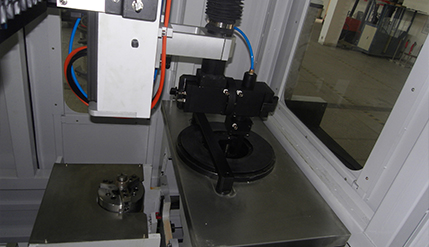

2.High quality: with auto pressing device, effectively reduce welding deformation, highly improve the production efficiency and quality.

3.Highly integration: integrated the auto preheat machine, melding main machine and unloading conveyor together.

4.Without space limitation, could weld small part and the parts of close interval.

5.Non-contact welding, greatly reduce the deformation and wear of the appliance.

6.Can weld various materials, and even any two kinds of various different textures and different natures can be welded well.

Our Company

WUHAN HANS GOLDENSKY LASER SYSTEM CO., LTD. is a subsidiary of Han's Laser, located in East Lake High-tech Development Zone, "China Optical Valley",Wuhan. It's subsidiary company of HAN'S Laser Technology Industry Group Co., Ltd, (stock code: 002008). We are high-tech enterprise specialized in R&D, manufacture and sales for complete equipment of high-power laser source, laser cutting, laser welding, laser fusion covering, laser heat-processing and high-speed laser punching machine. We also provide automatic processing solving plans.

We have 20 years of experience in laser equipment production,The main products are laser cutting machine, laser welding equipment, laser perforating equipment, laser cladding equipment.

Laser welding application

Laser welding is mainly used in automobile, tools, home appliance, steel industry and others, for example nest gear of transmission, flying wheel, airbag, rock arm, muffler, silicon oil shock absorber, hydraulic torque converter, wood saw blade, diamond saw blade, radiator of water.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam