Laser cutting is the use of focused high-power laser beam irradiation of the workpiece, so that the material is rapidly melting, vaporization, ablation or reach the ignition point, while the beam with the beam coaxial high-speed air blown molten material, in order to achieve the workpiece cut open. Laser cutting is one of the thermal cutting methods. Laser cutting and other thermal cutting method compared to the specific advantages can be summarized as the following aspects.

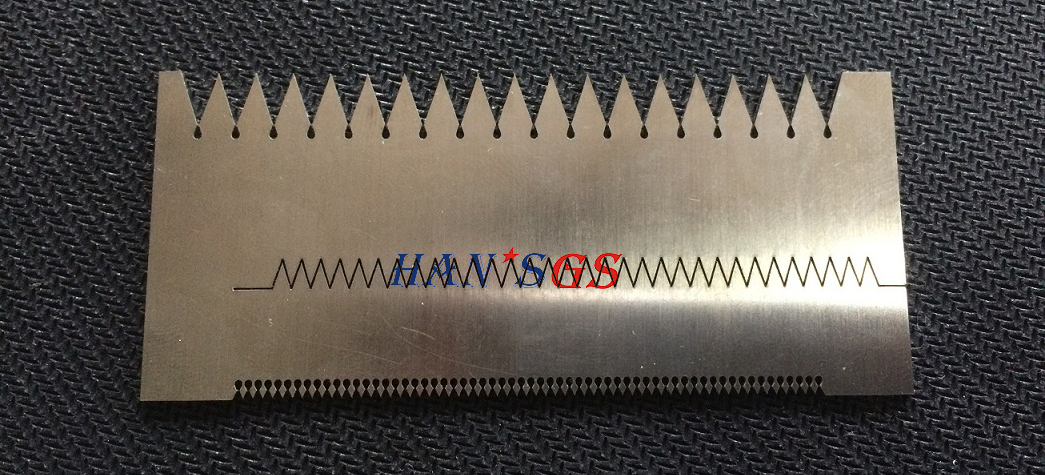

Cutting quality is good,the laser light spot is small, the energy density is high, the cutting speed is fast, so the laser cutting can get the better cutting quality.

1.Laser cutting incision narrow, both sides of the slit parallel and perpendicular to the surface, cutting parts of the dimensional accuracy of up to ± 0.05mm.

2.Cutting surface smooth and beautiful, the surface roughness of only a few tens of microns, and even laser cutting can be used as a last process, without mechanical processing, parts can be used directly.

3.After laser cutting, the width of the heat affected zone is very small, the performance of the material near the slit is almost unaffected, and the workpiece deformation is small, the cutting precision is high, the geometrical shape of the slit is good, and the cross section shape of the slit is more regular The rectangle.

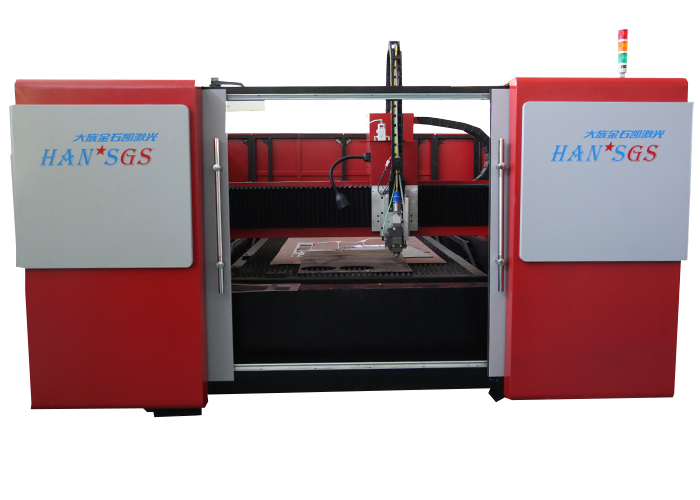

Cutting efficiency due to the transmission characteristics of the laser, laser cutting machine is generally equipped with multiple CNC table, the entire cutting process can achieve all the NC. Operation, just change the NC program, you can apply different shapes of cutting parts, both two-dimensional cutting, but also to achieve three-dimensional cutting.

Cutting speed with a power of 1200W laser cutting 2mm thick low carbon steel plate, cutting speed up to 15000px / min; cutting 5mm thick polypropylene resin board, cutting speed up to 30000px / min. Material in the laser cutting does not need to clamp fixed, can save fixture, but also save the upper and lower auxiliary time.

Non-contact cutting laser cutting torch and workpiece without contact, there is no tool wear. Processing different parts of the shape, do not need to replace the "tool", just change the laser output parameters. Laser cutting process low noise, small vibration, no pollution.

More types of cutting materials: Compared with oxyacetylene cutting and plasma cutting, laser cutting materials, including metal, non-metallic, metal and non-metallic matrix composite materials, leather, wood and fiber. However, for different materials, due to their own thermal physical properties and the absorption rate of different laser, showing a different laser cutting adaptability.

In the context of the market situation, the laser processing market has grown steadily. In the context of weak macroeconomic and industrial demand, laser processing equipment, with its business needs in the high-end processing market, has maintained a steady growth in the size of the industry. , Laser processing than the traditional machine tool cutting and other hot processing, with multiple technical advantages, and high-end processing market requirements of high precision, low wear and high efficiency requirements.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam