Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Address:No.72,Optical valley Avenue, East Lake High-Tech Development Zone,Wuhan.P.C:430223

Tel:+86-27-8792 4929

Fax:+86-27-8792 4929

Whats app:+86-18717170727

Skype:sales_hansgs@outlook.com

Email:hansgs@hansgslaser.com

2017-11-11

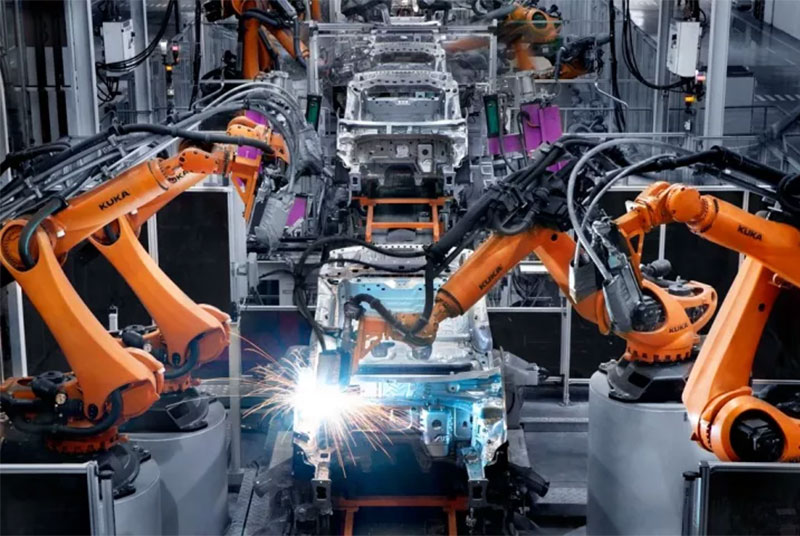

HANS GS takes you to visit SAIC Volkswagen Ningbo factory to uncover the mystery of laser welding. The way, TERAMONT , LAMANDO , SKODA OCTAVIA are produced here.

The most likely thing to say about SAIC Volkswagen is its body laser welding technology, which is still ahead of most of the joint venture brands and independent brands.But the laser welding is not only popular in use, Benz, BMW, Audi, Porsche and some other luxury cars on the basic use of laser welding technology, but used the popular models is the first volkswagen.

Ningbo Volkswagen factory workshop, the Skoda Octavia Travel Car BIW laser welding. There is a misunderstanding, the laser welding does not refer to all vehicles using laser welding, in fact most of resistance welding, electric welding and welding two, the actual use of laser welding, only the roof and the luggage compartment cover at several slightly long straight slot. Because the laser welding weld only enough length, tensile strength will exceed the tensile strength of the welding spot welding, and also closely related to the number of solder joints and spacing and other factors, so only the craft name does not explain what the weak strong, need to see the essence through the effect.

As for the benefits of laser welding, there is too much! For example, fast speed, tens of meters per minute, can speed up the production cycle, improve production efficiency. At the same time, this welding has small thermal deformation and high precision, and it will not cause load concentration phenomenon. Of course, laser welding will also contribute to the lightweight of the body, after all, the overlap area of sheet metal welding is reduced.

Laser welding brings enterprises the biggest advantage is the high degree of flexibility, now the major enterprises in particular flexible production line, in order to reduce the equipment cost and risk, the difference lies in can do several models of production line. The non-contact welding of laser welding will leave more space for the body clamp, and it can be put into production according to the different types of vehicles, and only need to change the fixture and the robot programming. In fact, the Ningbo factory is the same line production of TERAMONT , LAMANDO , SKODA OCTAVIA (travel version).

Laser welding benefits to users, may the appearance is more obvious, the roof is one, and some will need to cooperate with the spot weld roof rubber strip modesty".

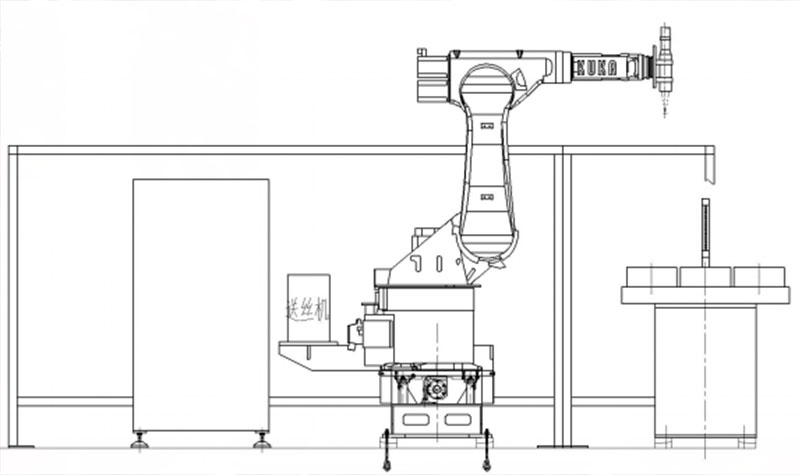

HANS GS Robot laser welding equipment consists of robot , fiber laser, laser welding head, refrigerator, mobile workstations, wire feeder, offline testing, seven-station rotary indexing table and welding fixtures and other components.

Features of the HANS GS robot laser welding equipment

1, A wide range of materials can be welded. Carbon steel, stainless steel, aluminum and other metals can be welded.

2, Three-dimensional welding robot software can be equipped, can achieve 3-dimensional welding.

3, A wide range of applications. Aerospace, locomotive manufacturing, engineering machinery, textile machinery, agricultural machinery, elevator manufacturing, automobile manufacturing, electrical hardware manufacturing, IT and other industries.

4, Low consumption. 4000W laser source consumes about 15 degrees / hour. Protection lens 0.5-1.0 yuan / hour.

5, High welding speed, high efficiency, safe operation and stable performance.

6, Provide smooth, beautiful welding appearance without deformation.