Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Address:No.72,Optical valley Avenue, East Lake High-Tech Development Zone,Wuhan.P.C:430223

Tel:+86-27-8792 4929

Fax:+86-27-8792 4929

Whats app:+86-18717170727

Skype:sales_hansgs@outlook.com

Email:hansgs@hansgslaser.com

2017-11-13

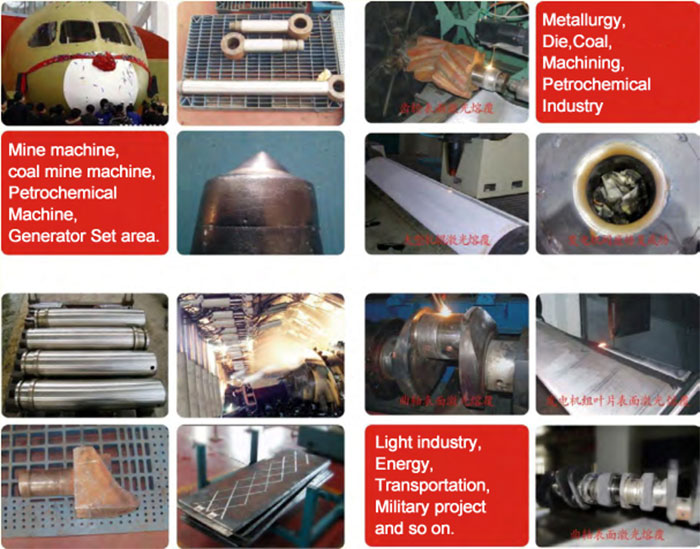

The power plant or other industrial manufacturing factories, metal parts in mechanical equipment wear often experiencing a huge challenge, in order to deal with these situations and prolong the service life of some special expensive production equipment, these devices need to be part of the appearance of metal plating on the special coating, such as the surface of the rotating parts, tubes and other functional components have a metal or ceramic coating.

In general, in order to prevent corrosion and wear of metal parts of mechanical equipment, it is often necessary to prepare special coating to protect parts. However, there are defects in the preparation methods of standard coatings such as hard chromium plating, thermal spraying, conventional laser cladding and surfacing:

Hard chromium plating environmental problems impassable. Protection of the most commonly used method of wear and corrosion resistance is hard chromium plating, but hard chromium coating and substrate is metallurgical bonding, easily destroyed, and the existence of micro cracks will weaken the wear resistance and corrosion resistance of coating. At the same time, the electrochemical reaction process consumes a large amount of electric energy, and the increase of power cost reduces the economic efficiency of the method. And this method would cause adverse effects on the environment, the EU regulations began only after authorization or approval before plating chrome since September 2017.

Thermal spraying low effective utilization of resources. There are also shortcomings of thermal spraying, the powder particles after plastic deformation by mechanical adsorption method combined with the matrix together, due to the combination of the mechanical adsorption is very fragile, so before application must be on the substrate surface roughening treatment. In addition, there is a void fraction of 1% - 2% in the coating, which leads to the need to prepare multilayer coatings to protect the parts adequately. The effective utilization rate of supersonic thermal spraying is also very low. It consumes hundreds of liters of gas per minute and only half of the powder material can form the final coating on the substrate surface.

Bead weld too much waste of raw materials. Welding process can produce high quality, tight with the substrate coating. A coating with a thickness of 2 - 3 mm can be produced by conventional processes such as tungsten inert gas welding or plasma arc welding, but the coating is too thick and wastes too much raw material. In the process of surfacing, the same amount of matrix material is melted and mixed with the coating material, so it is necessary to prepare multilayer coating to ensure the performance of the coating itself. Laser cladding can be used to prepare thinner coating with a thickness of 0.5 - 1 mm. Compared with the traditional process, the heat input can be reduced significantly, and the single layer coating can meet the requirements of the protection of the parts.