Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Address:No.72,Optical valley Avenue, East Lake High-Tech Development Zone,Wuhan.P.C:430223

Tel:+86-27-8792 4929

Fax:+86-27-8792 4929

Whats app:+86-18717170727

Skype:sales_hansgs@outlook.com

Email:hansgs@hansgslaser.com

2017-11-10

In the winter, the strongest cold air is coming. In view of the recent sharp drop in temperature, please do a good job in the cold wave period laser cutting machine antifreeze measures! HANS GS supply technical data and the most antifreeze solution.

First The basic principles and methods of antifreeze.

Liquids are "freezing point", when the liquid temperature is lower than the freezing temperature will be solidified to form a solid, and deionized water or pure water in the solidification of the volume will become larger, it will support the pipeline bad water cooling system and sealing connection damage. There are 3 solutions to avoid the damage of the laser, the output head and the water cooler due to the solidification of the cooling liquid:

1. If the local will not blackout, the night does not shut the water cooler, while saving energy, low temperature and Chang Wenshui temperature adjustment to 5 ~ 10 degrees, to ensure that the coolant is in a state of circulation, and the temperature is not lower than freezing point.

2. After the daily use of the laser, laser output head, water cooler cooling liquid emptying.

3. Use antifreeze as coolant.

Second Cooling water evacuation method and piping design scheme reference

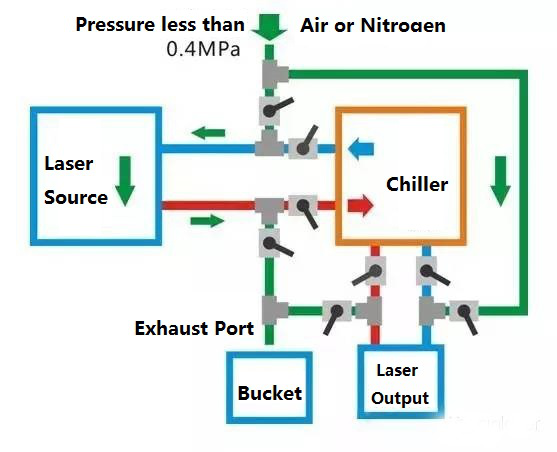

1.Schematic diagram of waterway connection

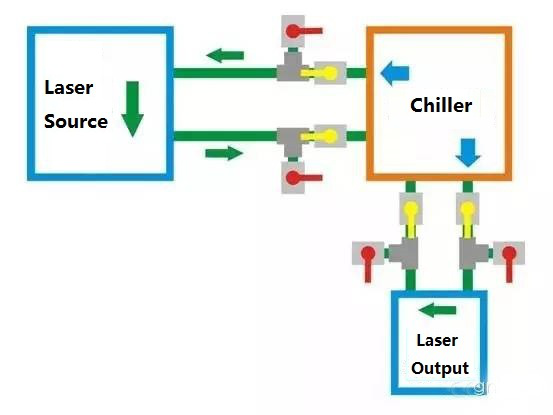

2.Normal use of the valve state (red shut yellow open):

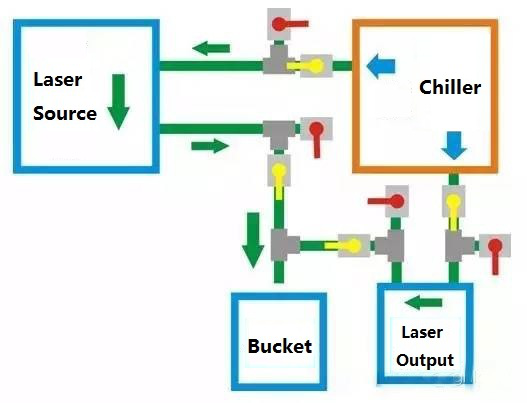

3.Before the shutdown, the chiller is used for active evacuation

When the water cooler starts up, the red valve is closed and the Yellow valve is opened, and the water cooling opportunity is to pump the water of the inner water tank into the water storage barrel until the water cooling power is turned off without a large amount of water flowing out.

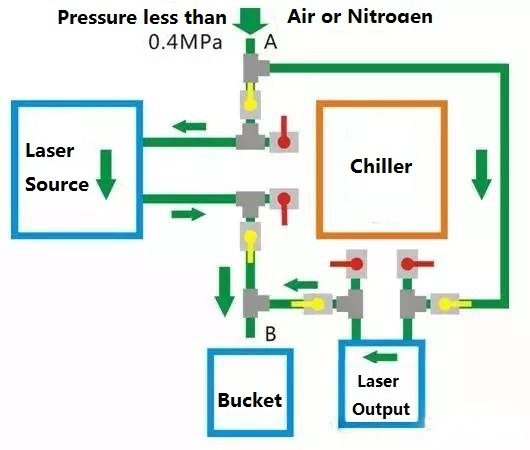

4.Low pressure air emptying residual water

According to the requirements of the diagram, close the red marked valve, open the Yellow marked valve, and enter the clean compressed air or nitrogen which is not higher than 0.4Mpa (4 kg) to the A, until the B point outlet has no water blown out.

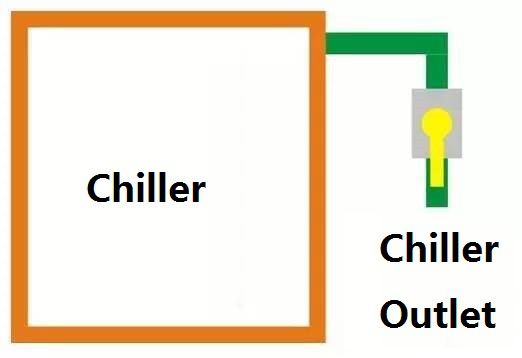

5.Chiller drain opening normally

Finally, Open the chiller outlet and drain the residual water in the tank.

Attention must be paid to all the cooling water discharged from the laser, laser output head, machining head and water cooler to effectively protect the whole water cooling pipe and related devices!

Third Use antifreeze

Antifreeze must be used when the environment is often cut off and there is no condition for the evacuation of the coolant every day. The basic liquid of antifreeze is composed of alcohols and water, which requires high boiling point and flash point, high specific heat and conductivity, low temperature viscosity, easy foaming, no corrosion of metal parts, rubber hose and so on. The freezing point should be 5 degrees lower than the minimum temperature in the use of antifreeze.

1. Use ethanol for short term antifreeze

If the power cut and can not drain the cooling water, the short-term need temporary antifreeze, can add ethanol to deionized water (or alcohol), add the amount can not exceed 40% of the volume of the water tank, because of the corrosive nature of ethanol is very strong, the grease, paint, rubber parts are corrosion, is corrosive to metals, therefore can not be used for a long time, must do the washing on the cooling pipeline emptying and pure water or deionized water within a week. Special antifreeze should be selected if antifreeze is still required.

2. Use special brand antifreeze

Recommended CLARIANT (Clariant) brand, antifreeze for laser system with two models:

1) Antifrogen, N, ethylene glycol - water type (industrial supplies, toxic to human body)

2) Antifrogen, L, propylene glycol - water (food grade, harmless to human body)

Caution: any antifreeze can not completely replace deionized water and can not be used for a long time throughout the year. After winter, the water must be cleaned with deionized water or purified water, and the deionized water or pure water should be used as the coolant.

If conditions permit, we still propose to improve the electricity environment, keep the water chiller without shutting down, or upgrade the cooling water path design, so that the daily cooling water emptying becomes simple and fast.