Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt NamAviation Industry

● Laser cutting and drilling,In aviation manufacturing industry, laser cutting technology is mainly used for cutting special aviation materials, such as titanium alloy, Aluminum Alloy, nickel alloy, chromium alloy, stainless steel, beryllium oxide, composite materials, plastic, ceramic and quartz etc.. Aerospace parts with laser cutting of the engine flame tube, titanium alloy thin-walled casing, plane frame, titanium skin, long tail, wing truss panel, helicopter rotor, space shuttle ceramic tiles etc..

● Laser welding,Aircraft manufacturing process used in laser welding of many places. Laser welding is widely used in the welding of thin-walled structures, the most typical aircraft structure is Aluminum Alloy European Airbus aircraft fuselage panel, the welding riveting structure will reduce the weight of the aircraft fuselage near 20%, reduce the manufacturing cost of about 20%, welding panel structure has been applied to the Airbus A318, A380 and A340 series aircraft.

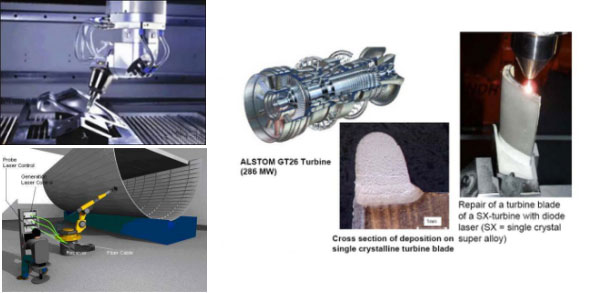

● Laser cladding,Aviation industry was the first to draw on the advantages of laser cladding for the production department, because it can not only be used for processing parts, and can be used for repairing parts.

Laser cladding is an important method of surface modification technology of materials. It is the use of high energy laser beam on metal surface irradiated by melting, rapid expansion and rapid solidification, with special physical, chemical or mechanical properties on the substrate surface cladding a layer of materials so as to form a new composite material, in order to compensate for the high performance of the body lacks, the composite material can give full play to the two the advantage of the lack of make up for each other.