Nesting Software Application for CNC Laser Cutting Machine

The Procedure of CNC Laser Cutting

According to Fabricating, the procedure of sheet metal laser cutting is as following:

1. Determine the materials to be processed and keep the sheet metal material fixed on the machine tool. Keep stable to avoid shaking when cutting. High precision comes along with high stability.

2. Using the nesting software set the cutting parameters such as CAD pattern, the thickness of material and so on. Then adjust the cutting head to suitable focus position and adjust the nozzle to suitable location.

3. Start the voltage stabilizer and chiller, setting the water temperature and water pressure.

4. Start the laser and machine tool.

Do you know the application of nesting software for CNC laser cutting machine?

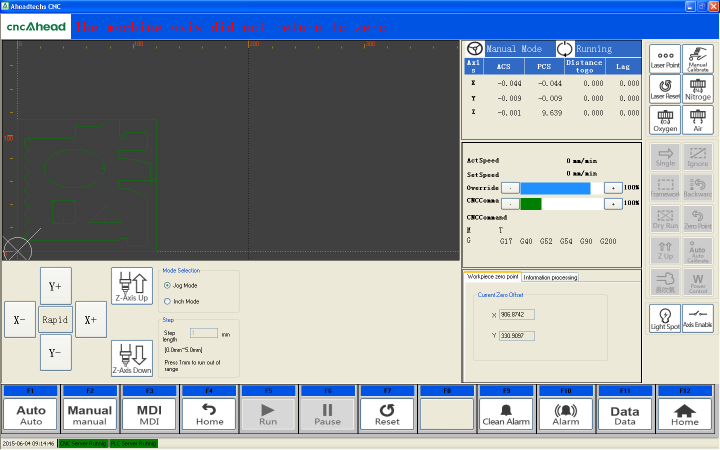

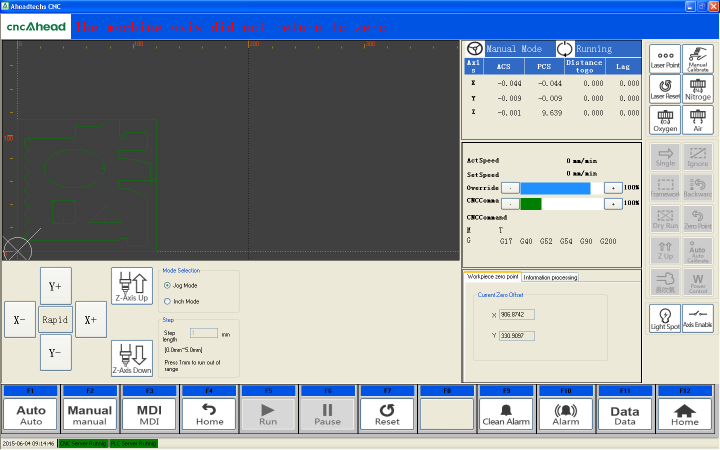

CNC stands for computer numerical control, and refers specifically to a computer "controller" that reads instructions, typically in G Code, and drives the machine tool, which is a powered mechanical device that is used to fabricate metal components by the selective removal of metal.

Computer Numerically Controlled (CNC) Programming is used in manufacturing to instruct CNC machines on exactly how to produce these components. The most commonly used language in CNC Programming is G Code.

1. What is G Code?

G Code is the common name for the most widely used control language for CNC machines. It is a way to instruct the CNC laser cutting machine to move

the tool to various points along a two dimensional plane or three dimensional space. Using G Code, the programmer may also specify the desired speed at which the tool should move, control the spindle speed, turn on and off various coolants, and many other things.

2. What is CAD/CAM?

CAD/CAM is the acronym for Computer Aided Design and Computer Aided Manufacturing. It is basically the use of computer systems for both design and controlling manufacturing processes. For instance, once a design has been produced with the CAD component, the design itself can be implemented in the CNC machines by the CAM component.

Nesting software make it easy to keep the good life with a CNC laser cutting machine:

From Wuhan Hans GS laser: www.hangslaser.com

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam