Laser application in the electronics industry

Laser processing can be used for micro-precision machining equipment, can be brittle semiconductor materials finely dicing, can also be used to adjust the micro-resistor. Laser processing technology is a non-contact processing methods, it does not produce mechanical compression or mechanical stress, specially designed to meet the processing requirements of the electronics industry. In addition, due to the advantages of high efficiency, pollution-free, high-precision and mall heat affected zone, it is widely used in the electronics industry.

Traditional phone keypad

Do you remember the popular long traditional mobile phone keypad?

Those are all using laser marking, buttons are made of transparent plastic and covered with a surface coating. This is just the tip of the iceberg. The mobile phone shell is made of titanium and stainless steel, keyboard holes on it are cut by a laser cutting machine . In the smart phone world, the laser is an important factor in the production of the touch screen. The sensor of touch screen connects the flexible printed circuit board with a layer conductive silver paste, the electronic circuit structure is finished with a laser, only laser has the ability to produce fine line structure with the least damage and heat influence.

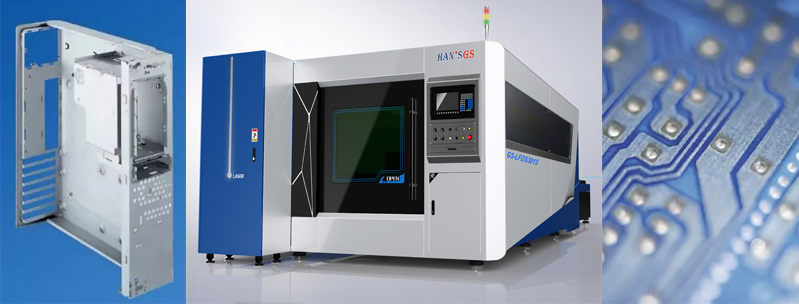

Electronic equipment enclosure

Electronic equipment, comprising a number of separate components susceptible to outside influence. Because they require a housing to support and protect. A typical case is made of a thin steel plate, the processing and forming of these cases are very flexibility, the laser beam can cut vents, openings and connecting holes in everything from the computer case to the CD player drive. Another laser beam is responsible for connecting the individual parts, solid-state laser welding visible edge computer casing or a fine welding in a smaller enclosure. You can use a special optical element of the laser beam splitter, and a plurality of welding points, reducing workpiece deformation while increasing processing speed.

Circuit board

Circuit board is the brain of electrical equipment. From coffee machine to the press bed, all of the circuit board contain the control circuit. Many processing of circuit board production are related to the laser. The printed circuit board is produced by a multistage chemical process, and therefore, each molding requires a separate mask. Laser ablation may be used for rapid prototyping, removal coating and writing circuit configuration. The distance between conductive path may be as small as 30μm. For rapid prototyping, laser ablation is faster than other methods, the price is cheaper. In the continuous production of printed circuit boards, the laser is used to drill holes to connect, out of the drilled hole is very fine diameter less than 100μm. Another application is trimming thick film resistors. Resistor film is initially applied too thick, the material with a laser beam ablation, until the desired value.

Hans GS new designed fiber laser cutting machine for metal cutting, you are worth to own. More laser equipment, such as laser welding, laser cladding, laser quenching, laser perforating, etc. Just visit our website: www.hansgslaser.com,

And can also leave a message for us, we will contact with you asap!

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam