Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Address:No.72,Optical valley Avenue, East Lake High-Tech Development Zone,Wuhan.P.C:430223

Tel:+86-27-8792 4929

Fax:+86-27-8792 4929

Whats app:+86-18717170727

Skype:sales_hansgs@outlook.com

Email:hansgs@hansgslaser.com

2016-07-26

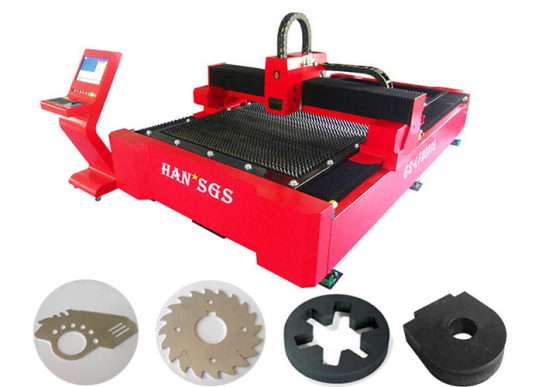

The importance of the servo motor for laser cutting machine

Servo motor is a very important part of laser cutter, its quality decides the stability of the equipment, especially in machining contour deformation. At present, the most used in laser cutting machine brand are Yaskawa, Panasonic, and Taida, etc.

How to be affected by servo motor for the operation of the laser cutting machine?

For laser cutting machine, both plate cutting and pipe cutting want the equipment processing in accordance with the established graphics, the key is to participate in the processing of each axle of dynamic response and cooperate with each other. If in the machining process, the overall response of the shaft is too slow, or certain position in an axis deviation is small, the other a large axial deviation, machining contour deformation problem will appear. And the cause of this deviation is numerous, have mechanical, external force, servo responsiveness, control system and other factors, or superposition of multiple factors. Therefore, the key to solve these problems lies in the axis good dynamic response and coordination of cooperation between each other, can make it more strictly carried out in accordance with the stated goal of processing actions. Servo motor as a carry on mechanical and control system in the middle of the actuator, can to some extent compensate for the motion, optimization and coordination system, in order to achieve a more perfect control purposes.

Han’s GS laser cutter use YASKAWA Servo Motor , it is strong rigidity, excellent control ability, accurate, sensitive response

1. Outstanding performance with the highest level of response of amplifier in the industry, the setting time is shortened in a high degree.

2. Enhancement of the Vibration suppression function to improve the track ability and decrease the setting time. Reduce the vibration when driving and reduce the fore-end vibration when stop working

3. Easy start up: simple installation and setting. The connection can be finished one time with Sigma Win+Connection confirmation function.

4. Standard configuration with analog quantity, instruction form of pulse sequence type and MECHATROLINK-II communication command type.

Want to learn more information, just feel free to contact us !

WUHAN HANS GOLDENSKY LASER SYSTEM CO., LTD.

Website: http://www.hansgslaser.com

E-mail:hansgs@hansgslaser.com