As we all know, the high precision and high efficiency of fiber laser cutting machines are the processing experts in the metal processing industry. However, these advantages are concentrated on the accessories of the equipment. Even if the same fiber laser cutting machine uses different accessories, the final cutting effect will be different. Therefore, if the user wants to purchase a fiber laser cutting machine, its accessories Matching is very important. Let's learn about the selection of the core components of the laser cutting machine.

How to choose the core components?

Fiber laser

Fiber laser is an important component of fiber laser cutting machine and the "power source" of the core of fiber laser cutting machine. At present, the fiber lasers with high configuration on the market are: German IPG, British SPI laser. Compared with other lasers, these two fiber lasers have high cutting efficiency, reliable quality assurance, long service life and low maintenance cost.

2. Stepper motor

Related to the cutting precision of fiber laser cutting machines, some manufacturers choose to import stepper motors, while others are produced by joint ventures. Some smaller companies usually choose brand-name motors.

3. Control section

The control system is the dominant operating system of the fiber laser cutting machine, and its quality determines the operational stability of the fiber laser cutting machine. It mainly controls the machine tool to realize the movement of the X, Y and Z axes while controlling the output power of the laser.

4. Cutting head

The laser cutting head is a laser output device consisting of a nozzle, a focusing lens and a focus tracking system. The cutting head of the laser cutting machine will walk according to the set cutting trajectory, but the laser cutting head needs to be adjusted and controlled under different materials, different thicknesses and different cutting methods.

5. Servo motor

The servo motor is an engine that controls the operation of the mechanical components in the servo system, and is an auxiliary motor indirect shifting device. The servo motor can make the control system accurate in position accuracy, and can convert the voltage signal into torque and speed to drive the control object. A good servo motor can make the cutting precision, positioning speed and repeat positioning accuracy of the laser cutting machine.

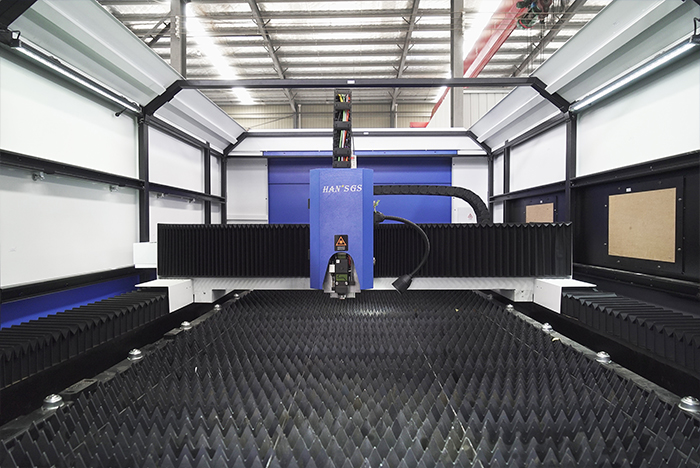

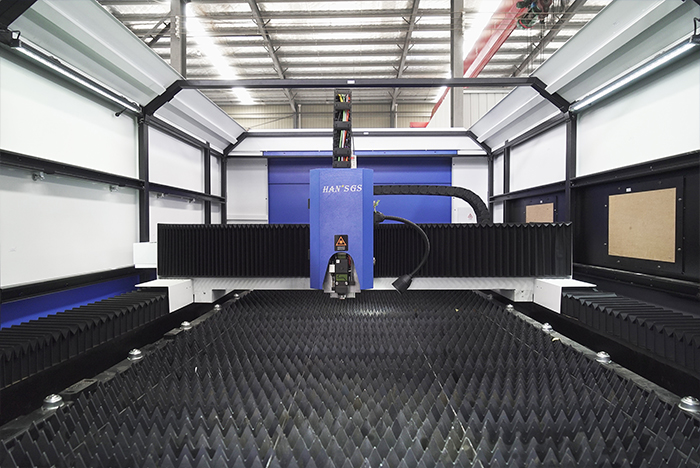

HANS GS LASER specializes in the production of laser cutting machines. It is a manufacturer of laser cutting machines, laser welding machines, laser drilling machines and laser hot-melting equipment. It can provide you with the right laser solution.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam