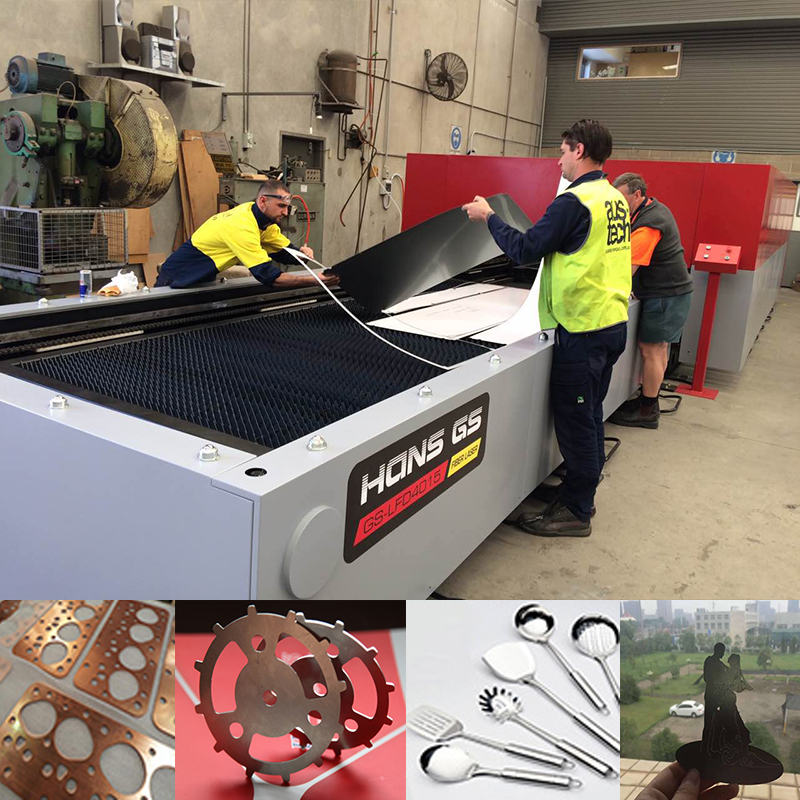

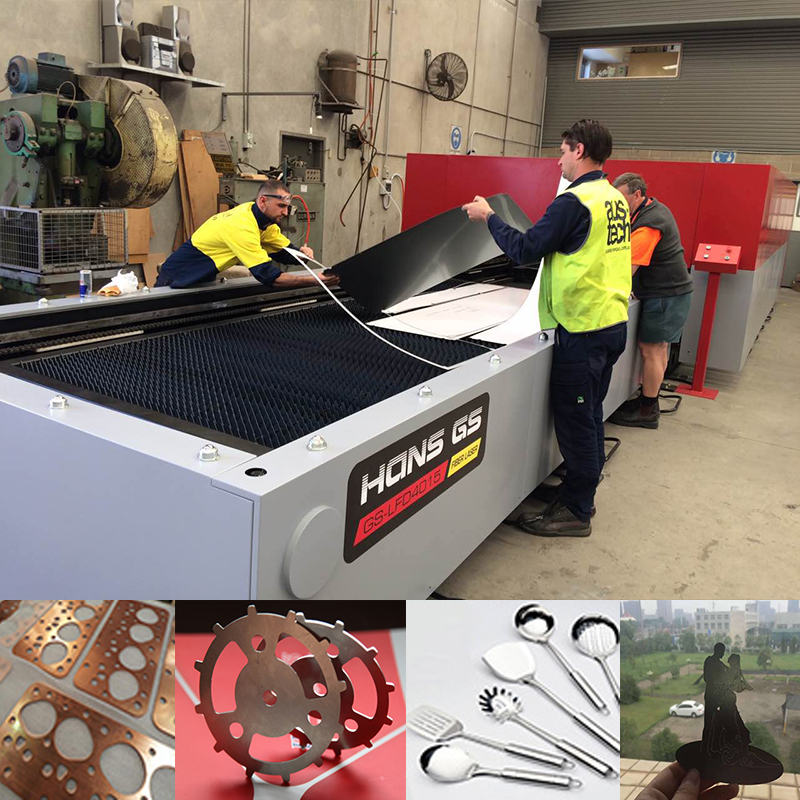

In recent years, fiber laser cutting technology has been widely used in the industry. In 2014, fiber lasers surpassed CO2 lasers as the largest share of laser sources.

Fiber laser cutting provides both cutting speed and quality achievable with CO2 laser cutting, while significantly reducing maintenance and operating costs.

The fiber-cutting technology has high energy efficiency. With the complete solid-state digital module and single design of the fiber laser, the fiber laser cutting system has higher electro-optical conversion efficiency than CO2 laser cutting. For each power unit of a CO2 cutting system, the actual general utilization is about 8% to 10%, while the fiber laser cutting system power efficiency is about 25% to 30%.

Fiber lasers have short-wavelength characteristics that increase the absorption of the beam by the cutting material and can cut materials such as brass and copper as well as non-conductive materials. A more concentrated beam produces a smaller focus and a deeper depth of focus, so that fiber lasers can quickly cut thinner materials and cut medium thickness materials more efficiently.

The CO2 gas laser system requires regular maintenance, the mirrors require maintenance and calibration, and the resonant cavity requires regular maintenance; the fiber laser cutting solution requires virtually no maintenance. Compared to CO2 cutting systems, fiber cutting solutions are more compact and have less impact on the ecological environment, so less cooling is required and energy consumption is significantly reduced.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam