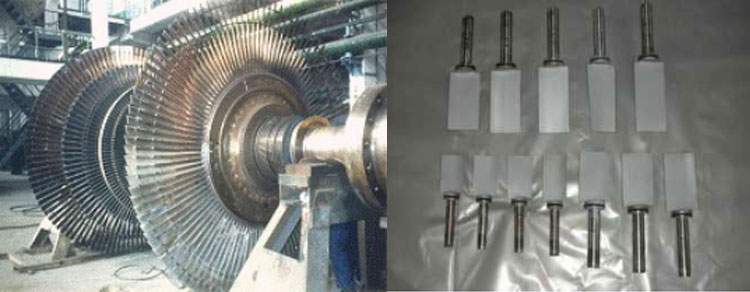

Laser disk laser cladding and repair

The key consumables of the smoke machine mainly include the discs and the blades. The appropriate laser cladding process is used to first flatten the grooves existing on the turbine disc and the sidewalls, and all the holes in the welding disc and the sidewalls are The cracks are then laser-clad and the alloy powders with the same properties as the substrate are laser-clad. It is possible to directly obtain a high hardness alloy layer without using a primer layer and without preheating.

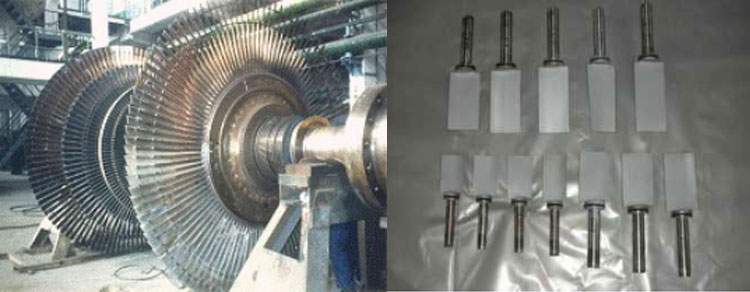

Laser cladding and repair process of turbine blades

(1) Pretreatment process: the basic process is the same as before;

(2) Defect inspection for repair welding: by naked eye observation and testing equipment detection, detect the areas that need to be repaired, including wear areas, crack areas, etc., and record the required repair positions;

(3) Laser cladding: For the fine cracks in the blade, if the pulsed YAG laser is used for repair, a more ideal effect can be obtained. Laser repair blades fall into two categories: one is the repair of micro-cracks and the other is the length of the leading edge of the wear blade. Pulsed laser cladding technology is used to control the laser cladding layer without cracks by controlling the laser input energy, repetition frequency, and laser scanning speed. The use of CO2 laser cladding can achieve considerable results.

(4) Subsequent processing: Grinding, polishing and trimming the repaired blades to meet the drawing requirements.

(5) Quality inspection: Quality inspection of the repaired turbine disk to confirm that the quality of all repaired parts meets the requirements.

(6) Finishing treatment: The surface of the inspected turbine disk is subjected to finish coating such as spray coating.

After the above treatment, the blade can be repaired as new.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam