Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Address:No.72,Optical valley Avenue, East Lake High-Tech Development Zone,Wuhan.P.C:430223

Tel:+86-27-8792 4929

Fax:+86-27-8792 4929

Whats app:+86-18717170727

Skype:sales_hansgs@outlook.com

Email:hansgs@hansgslaser.com

2018-02-27

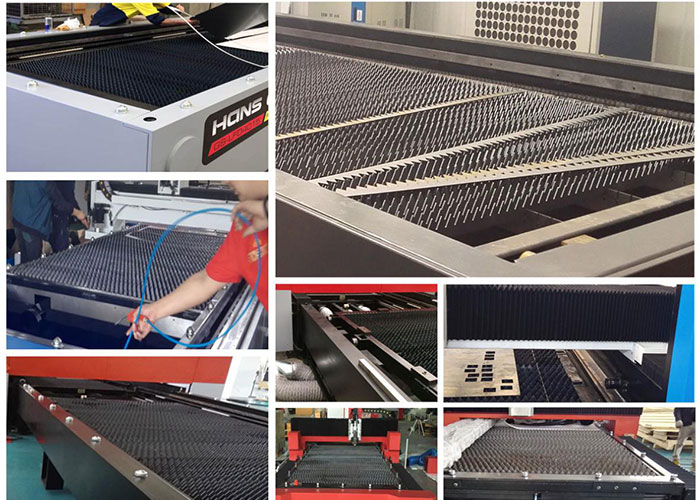

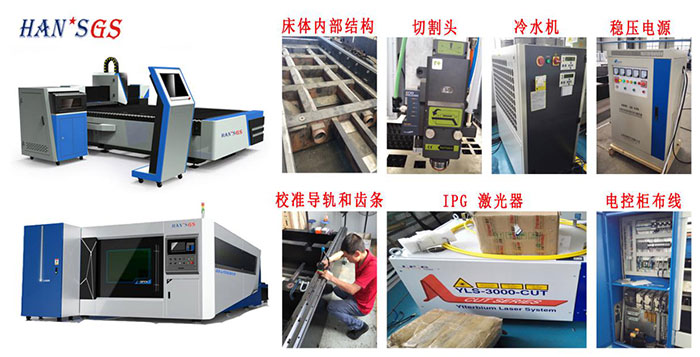

Gantry structure, gear and rack, bilateral drive... Do you know the characteristics of the HANS GS laser cutting machine?

1. What are the characteristics of the laser cutting machine?

The

application of laser cutting machine in industrial products has been

developing rapidly in recent years. Its near infrared wavelength

(1080nm) is also more conducive to the absorption of metal materials,

especially in the field of high-power welding and cutting, showing high

processing capacity and economy. Compared with the gas CO2 laser, the

fiber laser cutting equipment has the following characteristics: low

maintenance, low energy consumption and low operation cost; optical

fiber transmission, no need for reflective lens, no adjustment of

external optical path, low power consumption, no consumption of working

gas, energy saving and environmental protection. At the same time, the

near infrared wavelength laser is more likely to cause harm to the human

body, especially for the eye damage, which requires the equipment to

have better sealing and other protective functions.

2, why should the laser cutting machine adopt the gantry structure?

The

structural types commonly used in the CNC laser cutting equipment are

gantry type, cantilever type, intermediate hanging beam and so on. But

with the development of the application of laser processing to the

development of high speed, high speed, high stability and control

technology improvement, gantry type structure with its unique structure

and advantages become the mainstream models of the world structure is

also many well-known brands of laser cutting machine manufacturer using.

3. What are the characteristics of the laser cutting machine technology?

The

application of fiber laser cutting equipment in metal cutting is

different from traditional CO2 laser cutting machine. The change lies in

external optical path, cutting head, auxiliary gas and so on. The laser

can be directly through the optical fiber transmission to the cutting

head, the light path is stable and reliable to ensure consistency of the

machine tool cutting machine and the whole area, also do not need

optical protective gas, will be equipped with air compressor system;

cutting head after collimating and focusing laser, usually focusing lens

focal length 125mm or 200mm configuration and equipped with protection

to prevent contamination of lens focusing mirror to a focusing mirror

and a nozzle; good focusing performance of fiber laser with short focal

depth, cutting seam width narrower (up to 0.1mm), high speed, fast

cutting for thin plate.

4, why should the laser cutting machine use the gear rack to carry on the transmission?

Several

linear shaft transmission methods commonly used in CNC machine tools

include ball screw, gear rack and linear motor. The ball screw is

usually used in CNC machine tools in low speed travel; the gear rack is

moving a wide range of applications, which can achieve high speed, large

stroke; linear motor used in high speed CNC machine, special structure,

high acceleration. In addition, the gear rack is divided into two

kinds, straight teeth and skew teeth. Relative to the straight teeth,

the meshing area is larger, and the transmission between the gear and

the rack will be more stable.

5. What are the characteristics of the laser cutting machine's bilateral drive?

Gantry

type structure of laser cutting machine has two forms of movement, one

is the processing of gantry movement but the work table is fixed, the

two is the gantry fixed and worktable movement. For large format,

high-speed and high-performance laser cutting machine, the first form is

usually used, because the worktable with workpiece movement is not

suitable for high-speed and thick plate cutting. This bilateral drive

ensures the force balance of the beam and the beam runs synchronously.

The laser cutting machine of some manufacturers adopts gantry unilateral

drive, the servo motor is installed at one end of the gantry cross

beam, and then a long shaft is used to transfer the driving force to the

other end, so as to realize double teeth gear transmission and single

servo motor drive. The single side drive makes the force asymmetric at

both ends of the beam, affects the synchronization precision and reduces

the dynamic performance of the lathe.