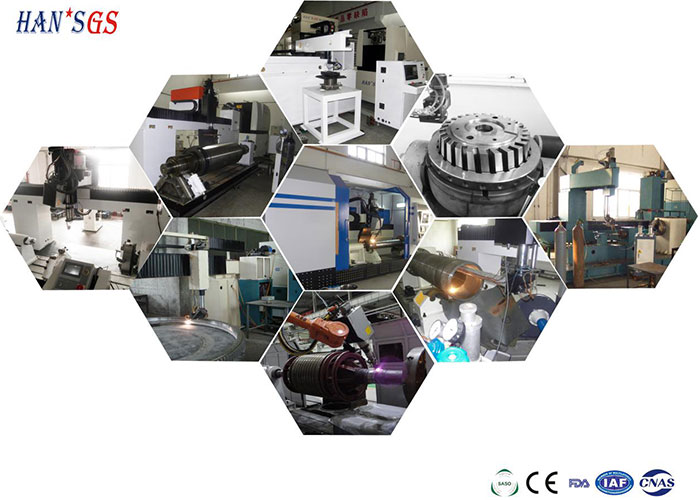

Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Address:No.72,Optical valley Avenue, East Lake High-Tech Development Zone,Wuhan.P.C:430223

Tel:+86-27-8792 4929

Fax:+86-27-8792 4929

Whats app:+86-18717170727

Skype:sales_hansgs@outlook.com

Email:hansgs@hansgslaser.com

2018-02-26

HANS GS laser cladding equipment Adding new kinetic energy to the steel industry

In a long period of time, the traditional industrial manufacturing process or reparation in China often requires electroplating technology. Although once in the electroplating technology of metal surface protection and decoration processing has played a significant role, and there are lots of application of functional electroplating technology in electronic industry, communication, military, aerospace and other fields, but the pollution problem has long been brought to many manufacturing enterprises headache.

Comparison of several repair methods for mill housing

1. Removal of mechanical processing

The way of online machining is to remove materials by mechanical processing, remove the damaged surface of the mill housing, and achieve the level of contact. The expanded size is compensated by increasing the thickness of the liner. This repair method is simple and convenient to operate, but it doesn't change the property of the mill housing. After a period of time, the surface of the mill housing will be corroded and worn out, and it will have an adverse effect on the strength and stiffness of the archway. Considering the sensitivity of the finishing mill to the stiffness, the allowance for processing is not much, and the repair method can only be a expedient measure.

2. Arc surfacing method

The arc surfacing method is to remove the size of the material after the machine is processed, and to build up a layer of anticorrosive and wearable material by on-site arc welding, so as to change the properties of the surface and improve the service life of the mill housing. A large area of arc surfacing on rigid structures such as the archway may result in the deformation of the archway structure. If the distortion and instability of the structure will be fatal, it is impossible to rectify it again, which is not allowed in the production of the factory. Therefore, the repair method will bring greater risk and generally do not use it.

3. laser surface cladding

The laser surface cladding has the characteristics of high energy density, dense cladding quality, high bonding strength, low dilution rate of microstructure of cladding layer and small heat affected zone. The laser surface cladding is non-contact processing and the input heat is controllable. The standard laser repair method can solve the welding residual stress and cracking tendency of other welding methods. Therefore, can use mechanical processing to remove corrosion and abrasion of the surface layer arch fatigue layer, and then select the corrosion resistance and wear resistance are better than the substrate powder by laser cladding to repair the mill housing, which avoids the defects caused by repeatedly removing material to decrease the strength of the mill housing, and avoid surfacing caused by the deformation caused by stress concentration, but also improve the arch corrosion resistance and wear resistance.

The main reasons for the abrasion of the rolling mill housing are as follows: 1. metal fatigue wear. 2,cooling water corrosion.3, during the operation of the rolling mill, bolts loosening and bolt lengthening of the fastening liners. HANS GS specializes in the development of a mobile robot laser remanufacturing equipment, in view of the large and poor movement of the mill archway.

Laser cladding is the use of laser to melt metal powder directly, and deposited layer by layer. The metallurgical quality of cladding coating finish of laser cladding technology of high and low dilution rate, small deformation, high surface smoothness, and environmental protection belongs to the advanced manufacturing and processing technology, greatly reduce the subsequent machining cost of enterprises in the industrial manufacturing field, can effectively extend the product life cycle, It is very popular in the repair of mill housing in iron and steel industry.

Field laser repair scheme for frame archway

1. Repair and processing methods

Because of the large volume and weight of the mill housing, the attached pipe line and so on, disassembly, installation and transportation are complicated, and the time limit of overhaul is also limited. The mill housing material is ZG25, the life life of the design is 40 years, the corrosion failure depth of the work face of the mill housing is 1 ~ 2.5mm. Based on the investigation and investigation of the working conditions, and considering the factors that satisfy the requirements, the field repair method for rolling mill housing is determined as follows:

Through online machining, removal of mill housing failure working face (four and two below the liner plate rolling mill bearing seat bottom surface) surface corrosion fatigue layer, upper surface corrosion is light, the lower half plane is more serious, the average milling around 2 or 3mm depth for laser cladding substrate before surface treatment to prepare. During the process of removing material and removing corrosion layer on the surface of the mill housing, we need to restore the verticality, flatness and roughness requirements of the failed working face (and installation surface). The special corrosion resistant material was remelted to the surface of the front surface by laser cladding technology, which completely changed the characteristics of the mill housing surface. It is estimated that the life of cladding coating is more than ten years, which avoids the harm caused by frequent machining and repairing on the surface of the mill housing, and solves the problem of abrasion and corrosion of the rolling mill.

In addition to the working face of the original processing method of bolt hole and the bolt holes are: cleaning, removal of broken screw thread damage, do re reaming tapping processing, laser cladding before the bolt hole to take appropriate measures to protect.

2. The principle of milling

1) The failure of the base surface of the sliding plate and the base of the bearing seat, and record the original size, the failure thickness and so on, and inform the user to confirm it.

2) To mill lining plate or the bottom of a supporting plane lining (slip) plate bottom surface (including the operation drive side and the transmission side entrance end of the outlet end of the transmission side, the bottom surface, the operation side entrance end and side outlet, the bottom of operating a total of six working face) as an independent unit for processing design.

3) The method of determining the thickness of the surface of the same lining (sliding plate) or the outside side of the operation rack is to detect and record before machining, and then select the actual wear condition and wear volume according to the determined datum size.

4) The principle of cutting and determining the milling quantity is the sensitivity of the mill to the stiffness, and the minimum cutting amount is the best under the condition of meeting the requirements of the machining precision.

5) In order to ensure the surface preparation of the following laser cladding process, all the surface corrosion layer and surface fatigue layer are removed by on-line mechanical machining.

Re manufacturing mill processed by laser technology, not only can make the site of injury recovery in size, improve the hardness and wear resistance, thereby improving the service life, it can ensure the use of 8-10 years, reduce the purchasing cost of new products, mobile repair can achieve fast repair, repair for mills to save time can also make the corrosion resistance to meet or exceed the new level.