Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Address:No.72,Optical valley Avenue, East Lake High-Tech Development Zone,Wuhan.P.C:430223

Tel:+86-27-8792 4929

Fax:+86-27-8792 4929

Whats app:+86-18717170727

Skype:sales_hansgs@outlook.com

Email:hansgs@hansgslaser.com

2018-02-01

Advantage of optical fiber output semiconductor laser source in laser cladding equipment

Laser cladding includes two parts: first, remanufacturing and repairing all kinds of metal defects, such as wear, corrosion, chrome marks, scratches and strains. Second, surface modification is required for parts that need hardness, abrasion resistance, corrosion resistance, high temperature resistance and no magnetism.

Customers who buy laser cladding equipment need to buy a device that can perform the above two functions at the same time. The main technical parameters in laser cladding process are three: the surface of high power density, so that it can be a variety of cladding materials (including ceramics, refractory materials such as tungsten carbide) formation of molten pool to achieve metallurgical bonding with the substrate; large spot rapid cladding, meet all kinds of large, large area defect repair or surface modified cladding; small laser cladding, meet various high precision parts, thin-walled parts, easy deformation of cladding parts requirements. At present, there are three kinds of equipment used in the laser cladding market, namely, CO2 laser source, semiconductor laser source, and YAG laser source .

Because of the CO2 laser wavelength of 10.64 m, 10 times of semiconductor laser, YAG laser wavelength, the same output power equipment, the surface power density of carbon dioxide laser cladding in the semiconductor laser and YAG laser in 1/3, and the heat affected zone is three times of semiconductor laser and YAG laser. In order to increase the surface power density, the output power of the equipment must be increased, so the output power of the carbon dioxide laser in the market is very large. On the one hand, the cost of equipment purchase is increased. On the other hand, CO2 laser equipment is huge, and it is not suitable for on-site repair and cooperation with all kinds of cladding tooling. Carbon dioxide laser operating costs, high maintenance costs, changing the vulnerable parts of high frequency and high price. Especially, the heat affected zone of CO2 laser is very high, and the thermal deformation rate of the clad parts is high. It is necessary to heat treatment the cladding parts in the process of cladding and cladding. Therefore, CO2 laser source is not the best choice for the laser metal cladding process.

YAG laser is the mode of pulse output, and the heat effect of the cladding substrate is very low. It can repair thin parts, small parts and high precision deformation parts. YAG laser structure is simple, easy to repair, low price accessories, is the initial repair industry entrepreneurs, the melting amount is not a large unit of the preferred equipment. The disadvantage of YAG laser is the low conversion rate of electro-optical conversion, which is only 5%. Because of the limitation of luminous principle, it can not produce high-power laser equipment over 1000W. Therefore, the output power of YAG laser is small and the cladding efficiency is low, so it is not suitable for large parts and large area cladding. The direct output of semiconductor laser applications currently on the market, the output power is 2000W-6000W, the semiconductor laser has the advantages of small size, light weight, the conversion reached 50%, the output laser wavelength of 808nm, 976nm, 1064nm etc., solves the disadvantages of large volume, heavy carbon dioxide laser, the output laser wavelength etc.. The problem that the YAG laser can not produce high power output laser is solved. But the direct output of the semiconductor laser has two fatal weakness: one is because the direct output of the semiconductor laser beam shaping is difficult, difficult to be laser beam shaping to very small, so the direct output of the semiconductor laser can not be thin and small, high precision variable shaped parts cladding; two is the direct output of the semiconductor laser is directly facing the laser cladding pool, heat radiation on the substrate bar laser light damage, although some domestic companies claim to be able to solve the problem of heat radiation in laser molten pool back light technology, but after the market test, the anti back technology is not mature, return the phenomenon of large-scale equipment. The best laser in the world is the optical fiber semiconductor laser, but the price is expensive. The high quality beam of the optical fiber semiconductor laser is a waste to the cladding process. Because the cladding process does not require minimal light spots below 1mm meters. Light semiconductor laser vulnerable parts are expensive and have long after - sale time, which can not meet the continuity of the cladding process. Because the maintenance is characterized by the fact that most of the repaired parts are discontinued for repair, and the repair period due to the delay of the laser equipment will cause huge losses to the discontinued enterprises.

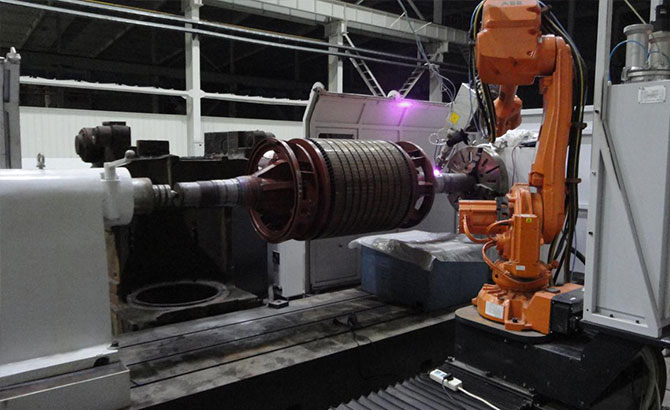

The way to solve all kinds of cladding functions of CO2 laser, YAG laser and direct output semiconductor laser is to choose fiber output semiconductor laser. The fiber laser output advantage: a semiconductor laser beam through the optical fiber transmission output, can complete the small light spot and then complete the output, thin-walled parts, small deformation, cladding parts with high precision; two, the semiconductor laser beam through optical fiber to output beam power density distribution, no slag, molten pool of laser the cladding splash is low, the cladding layer and no air; three, the output of semiconductor laser optical fiber communication long distance optical fiber head has the advantages of small size, weight easily with various cladding tooling, with the use of mechanical hand; four, semiconductor laser through optical fiber transmission output, solve the direct output of the semiconductor laser light radiation problem caused by the molten pool damage to the laser; five, the output of semiconductor laser has the advantages of small size, light weight, simple operation, maintenance free, the price and output of the semiconductor laser direct price When. At present, the HANS GS laser cladding equipment is all selected by the German LASER LINE semiconductor laser.