The fiber laser cutting machine has been able to gain a fast

foothold in the market and replace the traditional cutting technology

step by step, because its unique advantages in all aspects, so where is

he excellent? We know that the CO2 laser cutting machine and the YAG

laser cutting machine are compared.

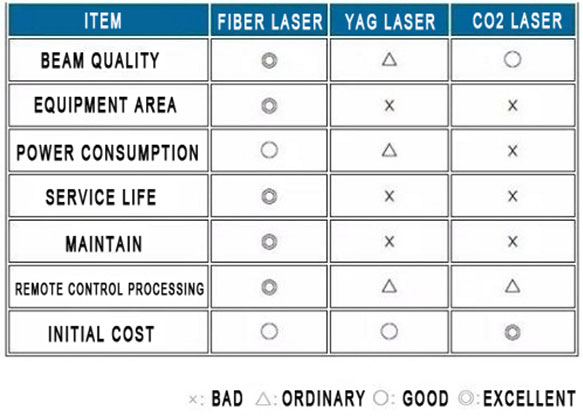

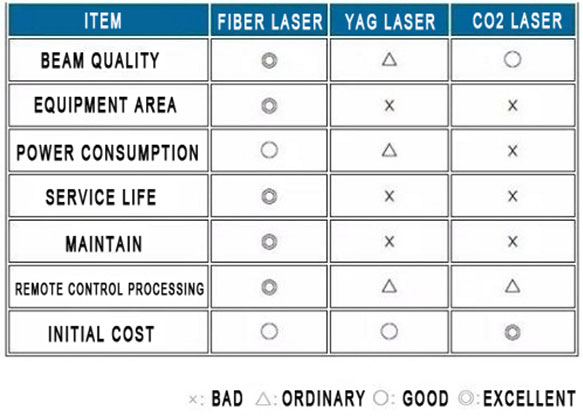

Contrast reference table for fiber laser, YAG laser and optical fiber laser

Co2 laser cutting machine VS optical fiber laser cutting machine

1. The point of view of processing

On

the one hand, CO2 laser cutting machine has wide cutting range, capable

of cutting thick metal plates and high reflective materials such as

aluminum plates. For non-metallic materials, such as acrylic, wood and

PVC, CO2 laser cutting machine can cut 60 mm thick. And the CO2 laser

cutting machine is a continuous laser. The cutting surface is smooth and

the cutting quality is good.

On the other hand, the CO2 laser

cutting machine is very slow, although the cutting seam is fine. The

cutting speed of the same power fiber laser cutting machine is 2-3 times

higher than that of the CO2, and the cutting section is smooth. In

addition, the beam has a large divergence, which is not suitable for the

processing of large scale.

2. The cost point of view

The

maintenance cost of CO2 laser cutting machine is higher than that of the

front end mirror. The cost of the front end mirror is only 8000 hours,

and the replacement cost is 80 thousand yuan per pair. At the same time,

the CO2 laser cutting machine will produce gas consumption, and the

photoelectric conversion rate is only 8%-10%. The optical fiber laser

cutting machine is basically processed without consumable material, and

its photoelectric conversion rate can reach 30%, and the energy saving

and electricity saving is compared.

3. The point of view of maintenance

The

CO2 laser cutting machine has complex structure, inconvenient

maintenance and high operation requirements, while the fiber laser

cutting machine is relatively simple to maintain, and is capable of

working in harsh working environments. It has high tolerance to dust,

shock, impact, humidity and temperature.

YAG laser cutting machine VS optical fiber laser cutting machine

1. from the point of view of processing

YAG

laser cutting machine purchase cost is low, can cut high reflective

material, such as aluminum, copper and other optical fiber laser cutting

machine can not cut the non-ferrous metal material. But the YAG laser

cutting machine almost cuts the small power laser cutting. It can only

cut thin plate material less than 8 millimeters. Compared with fiber

laser cutting machine, the cutting efficiency is much slower than

optical fiber, and the efficiency is relatively low. Optical fiber laser

technology can achieve very high power in very small package, so it

occupies less space and saves space.

2. from the cost point of view

YAG

laser is a kind of laser which has developed for several decades, and

the technology is mature, so the price of YAG laser cutting machine is

also relatively cheap. But with the popularity of fiber lasers, this

advantage is becoming weaker and weaker. In addition, the power

consumption of the YAG laser cutting machine is larger.

3. from the point of view of maintenance

Because

of the non optical lens in the resonator of the fiber laser, it has the

advantages of free adjustment, maintenance free and high stability, so

the device maintenance and replacement is relatively simple. This is

incomparable to the traditional YAG laser.

When two rounds of PK came

down, we found that the advantages of the optical fiber laser cutting

machine were more obvious. But the three kinds of laser cutting machines

have their own characteristics. In practical applications, they should

be chosen according to their own cutting needs and budgets.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam