The temperature requirements for the stable operation of the laser source are as follows:

The operating environment of the laser requires the following table that the temperature is between 5-45 degrees centigrade, and if it exceeds this range, the laser can not only be unstable.

It is decided that a serious person can even cause damage to the laser, such as the internal cooling water pipe road freezing.

N | Characteristics | Min. | Typ. | Max. | Unit |

1 | Operating Ambient Temperature Range | 5 |

| 45 | C |

2 | Humidity, Ambient Temperature Range ≤ 40°C | 10 |

| 95 | % |

3 | Storage Temperature without water | -40 |

| +75 | °C |

It is easy to cause laser source (including water cooler) to freeze (not limited to)

- The temperature is below zero, there is no heating, and the laser stops running for a long time.

- The temperature is lower than zero, and there are heating facilities, but the laser is stopped running for a long time due to the shutdown of the heating power supply (such as the Spring Festival).

- Water cooler is outdoors.

The harm caused by the freezing of the laser source (including the cold water machine) and the preventive measures.

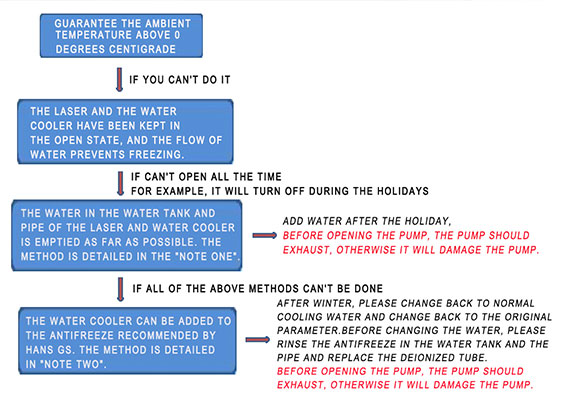

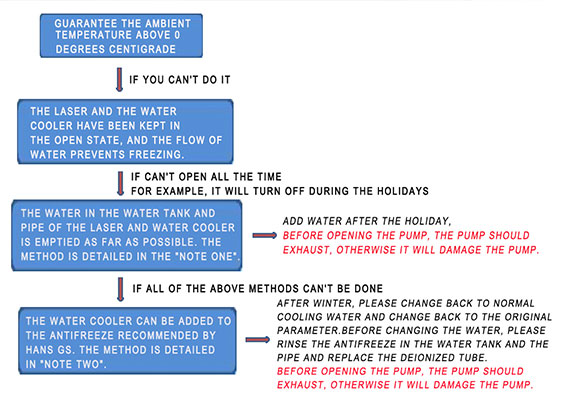

It is well known that the density of ice is less than water, and the volume of cooling water that flows through the core components inside the laser will expand once the volume of the cooling water is frozen.The serious damage of the pipeline is caused, and the safety of the core components is seriously affected, and the major loss is caused. In order to avoid the occurrence of this situation,The following measures should be taken less.

Note 1: the way to evacuate the water in the water tank and pipeline of the laser and water cooler

1. First, according to the usual method, the water inside the water cooler water tank is put out.

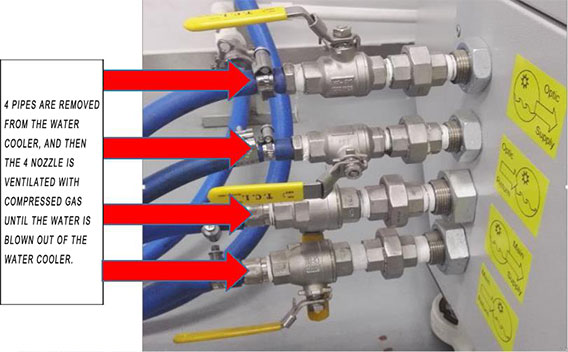

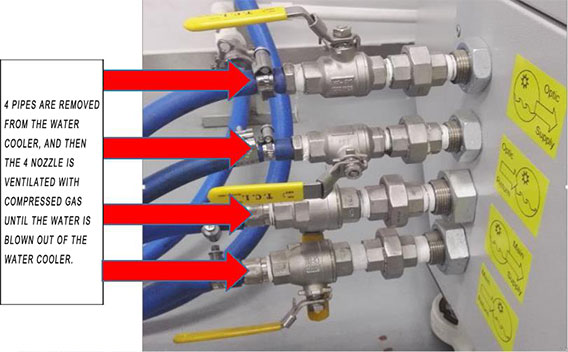

2. The water in the pipe of the water cooler is emptied as far as possible. Remove the water pipe from the water cooler and use the compressed gas less than 3.5Bar to ventilate 4 inlet and outlet ports until the water in the water cooler line is basically discharged. The 4 inlet and outlet ports are shown below.

3.After dismantling the two fast plug pipes of the deionized bucket, the compressed gas is blown from top to bottom, and the residual water in the deionized bucket is blown out. Then put the up and down fast plug pipe back to the ion bucket. This can ensure deionized bucket not because of ice and frost.

4.We will remove the water pipe from the inlet and outlet of the laser terminal, and use the compressed gas with a pressure less than 3.5Bar to ventilate 4 entry and exit ports until the water in the water inside the laser is basically discharged.

5.Finally the water in the other pipe lines outside the laser and water cooler is also discharged.

6.Note two: adding antifreeze method

7.The water cooler can add Clariant's AntifrogenN antifreeze.

8.The addition ratio is 3:7 (3 is antifreeze, 7 is water), and after adding antifreevze, it can resist -20 and no ice.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam