For the early entry novice, encountered poor quality cutting will not face puzzled, how to adjust the parameters of many. Below is a brief introduction to the problems and solutions.

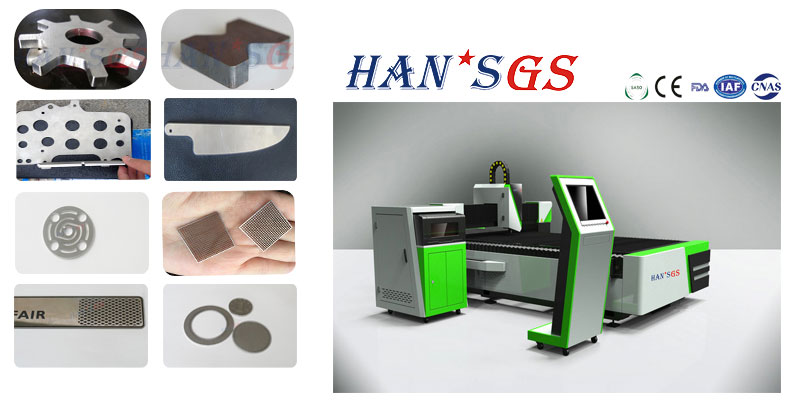

The parameters affecting cutting quality include cutting height, cutting nozzle type, focal position, cutting power, cutting frequency, cutting duty ratio, cutting air pressure and cutting speed. The hardware conditions are: protecting lenses, gas purity, sheet quality, Focus lens and collimating lens.

When the cutting quality is poor, it is suggested that a general examination should be carried out first. The main contents and order of the general inspection are as follows:

1.Cutting height (suggested that the actual cutting height is between 0.8~1.2mm), if the actual cutting height is not allowed, it needs to be calibrated.

2.Cut nozzle check whether the size and size of the cutting nozzle is wrong, if it is correct to check whether the nozzle is damaged or not, the roundness is normal.

3.Photocentric recommended cutting nozzle diameter of 1 light for inspection, inspection center focus best in -1~1. The light points that come out in this way are small and easy to observe.

4.Protection lens check to protect the lens is clean, water free, no oil, no slag point. Sometimes it will cause the fog to protect the lenses because of the weather or the overcooling of the paving gas.

5.Focus check focus is set correctly. If it is an automatic focus cutting head, you must use the mobile APP to see if the focus is correct.

6.Modify the cutting parameters.

After all the above six items are checked and have no problems, we can modify the parameters according to the pertinence of the phenomenon.

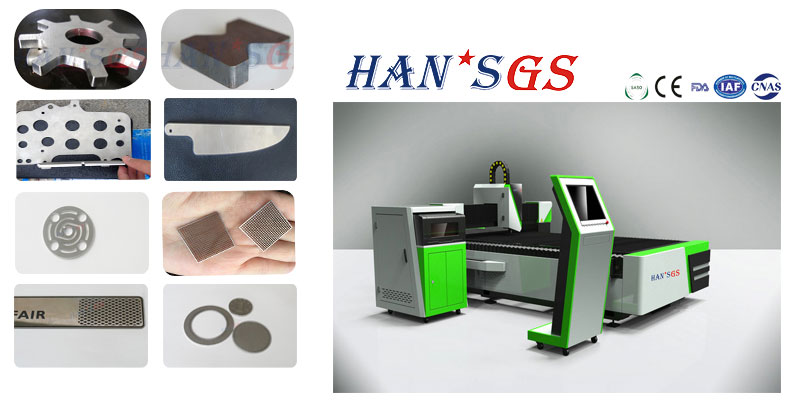

How to adjust the parameters according to the phenomenon, the following briefly introduces the state and solutions when cutting stainless steel and carbon steel.

For example, stainless steel slag, there are many types of slag. If only the angle of the corner can be taken into consideration, the corner and the circle can be considered, and the parameters can reduce the focus and increase the pressure.

If the whole hard slag is hung, it is necessary to reduce the focus, increase the air pressure and increase the cutting nozzle, but the low focus or the pressure over the assembly leads to the stratification and the roughness of the surface. If the whole granular soft slag is hung on the whole, the cutting speed can be increased or the cutting power can be reduced.

Cutting stainless steel may also be encountered: cutting the end of the cutting side of the slag, can check whether the gas supply gas flow is not enough to keep up.

Cutting carbon steel generally meets: thin plate section is not bright, thick plate cross section and other problems.

In general, a 1000W laser can cut light not more than 4mm carbon steel, and 2000W is 6mm and 3000W is 8mm.

Want to put the first light section cut plate surface without rust free paint nonscale, followed by high oxygen purity of at least 99.5% or more, need to pay attention to the cutting with a small cutting nozzle layer 1 or 1.2, the cutting speed is faster than 2m/min, need cutting pressure should not be too large.

If you want thick plate cutting section quality is good, first of all, we must ensure that the purity of plate and gas is followed by the selection of cutting nozzle. The bigger the hole is, the better the quality of section will be, but at the same time, the section taper will be bigger.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam