Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Address:No.72,Optical valley Avenue, East Lake High-Tech Development Zone,Wuhan.P.C:430223

Tel:+86-27-8792 4929

Fax:+86-27-8792 4929

Whats app:+86-18717170727

Skype:sales_hansgs@outlook.com

Email:hansgs@hansgslaser.com

2017-11-30

As we all know, reducing coke and reducing damage is the trend of the global tobacco industry. The National Tobacco Monopoly Bureau is also actively promoting the "reducing coke and reducing coke" project. At present, the average tar content of Chinese cigarettes has been reduced from 20 years ago to 15mg per branch of 30mg, and the average value of the tar is reduced to 0.5mg again each year.

Therefore, in recent years, the world's tobacco producers, research institutes and manufacturers are adopting various means, such as chemical coke reduction, physical char reduction, and so on, to reduce tar content in cigarettes.

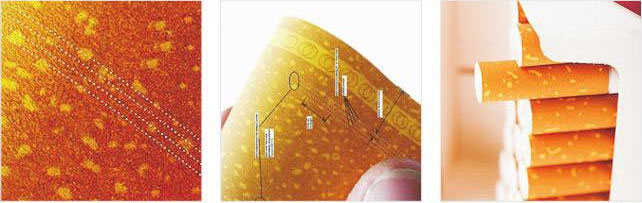

Research shows that people in the process of smoking can reduce the intake of harmful substances such as tar, nicotine and carbon monoxide by air dilution, and the high porosity of cigarette paper and pre perforated tipping paper (paper) came into being. Especially the technology of pick up paper drilling has been developing rapidly in recent years, because in various ways, the method of quantitative drilling with laser butting paper is the most simple and effective way.

Tipping paper laser perforating , tar harm reduction

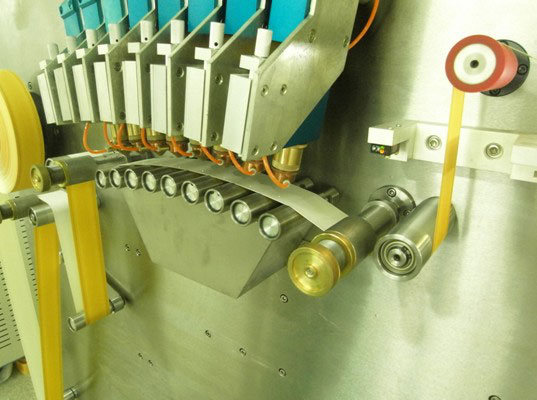

Tipping paper laser perforating equipment produced by WUHAN HANS GOLDENSKY LASER SYSTEM CO., LTD., not only has completely independent intellectual property rights, but also by the state tobacco monopoly administration achievements, and has reached the international advanced level in technology.

Tipping paper laser perforating equipment mainly used in cigarette production equipment supporting enterprises, since the market, by domestic and foreign customers praise, sales are increasing year by year. This set of equipment by laser perforating of cigarette filter paper and special production line, realizes coke filter ventilation, thus reducing the harm of smoking on the human body. The number of the laser head can be customized according to customer demand, the production cycle is short (2 weeks), the product performance is stable, all day long 24 hours of uninterrupted work, and life in 10 years, and the laser head can be in tipping paper made of various combinations of special-shaped holes, satisfy the customer as a means of anti-counterfeiting technology demand.