Laser cutting machine is often used in drilling metal materials. The accuracy of drilling is an important part of measuring the quality of laser cutting machine. In fact, the accuracy of laser cutting machine does not depend entirely on the equipment itself, but is made up of many factors.

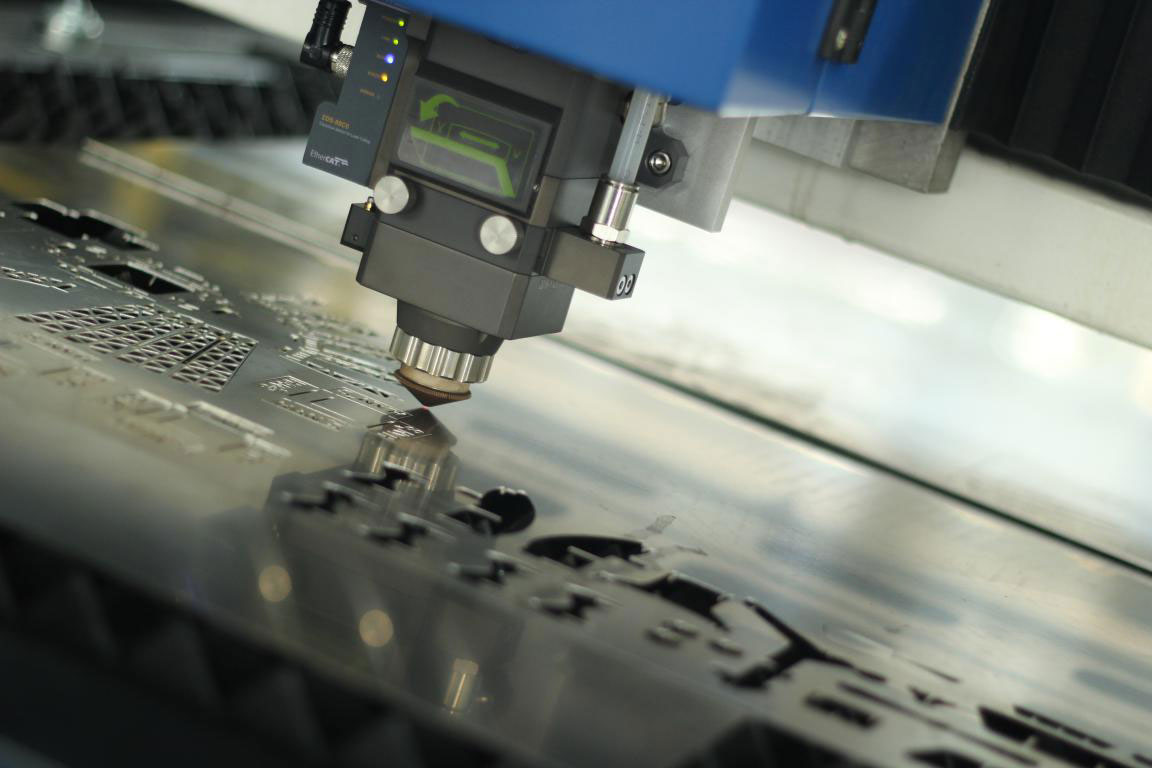

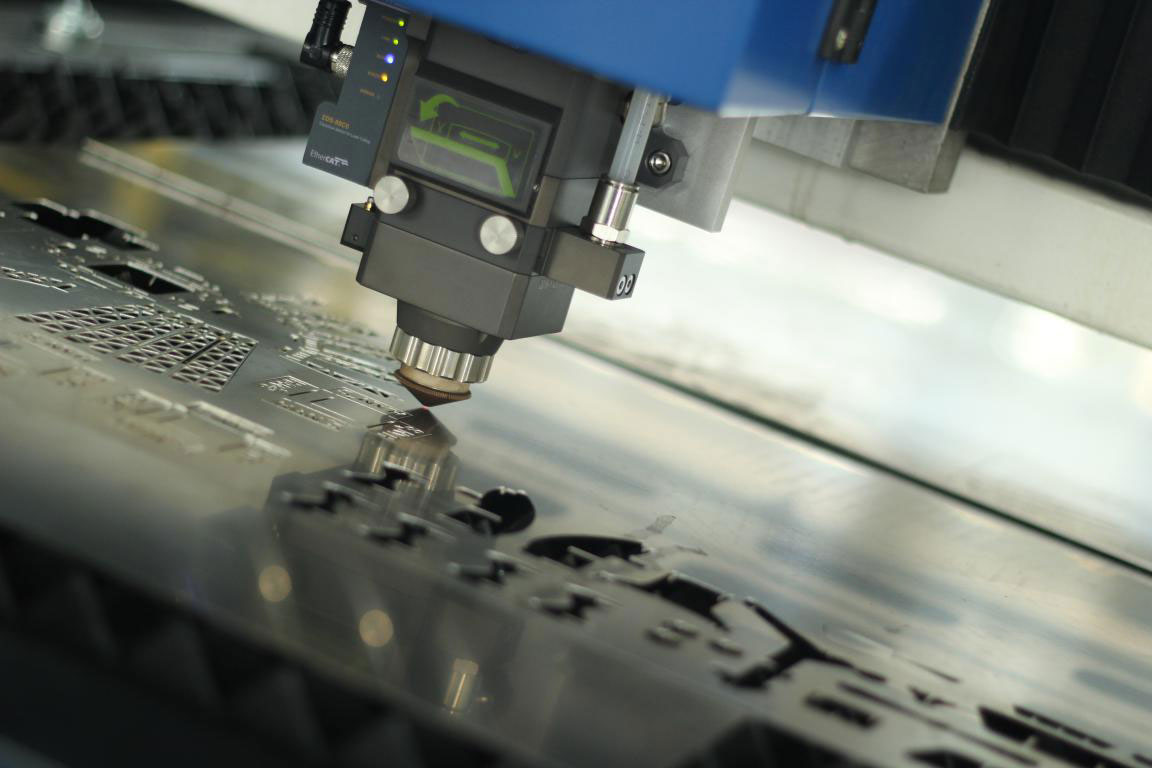

1)Cutting Head. Using the cutting head of a particular configuration, cutting the 0.5mm plate, the minimum cut between the stripes can be achieved by 0.1mm; cutting the 0.5mm plate, cutting out the smallest round diameter of about 0.45mm.

2)Laser Source. A laser with a small divergence angle (0.001 ~ 0.003rad) can shorten the focal length or reduce the output energy, and a small aperture can be obtained. High melting point. Micro hole machining of high thermal conductivity materials can realize the pore size of 0.01 ~ 1mm, the minimum diameter of up to 0.001mm; increase the laser output energy, the pulse width of the reasonable (materials and better thermal conductivity, it should take the pulse width shorter), application mode (single Gonjo Goss distribution) can obtain a large deep hole. For small holes with small apertures, the laser should be irradiated many times and punched with an objective lens with short focal length (15 ~ 30mm).

3)Increasing roundness of laser machining holes. The laser mode adopts the fundamental mode machining, the focusing lens uses the spherical aberration objective lens, and the optical axis of the lens coincides with the laser beam axis, the workpiece is suitable for deviation from the focusing point, and the proper laser energy is selected, etc., and the processing roundness can be improved.

4)Reduce the taper of the drill. Usually with taper hole aperture ratio increases, the laser output energy or small energy appropriate multiple irradiation, short focal length, the refractive index of the lens and reduce the angle of incident light and the optical axis between the measures can reduce the small hole taper.

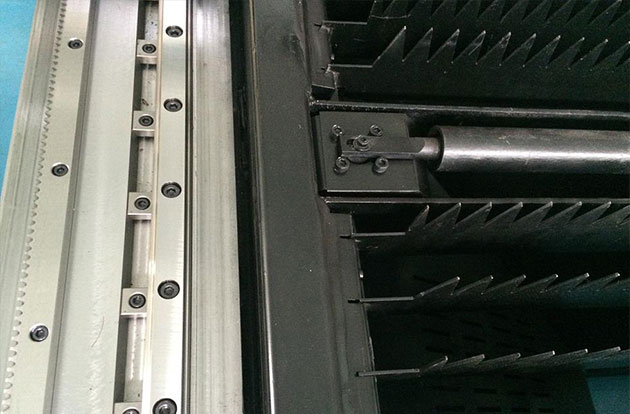

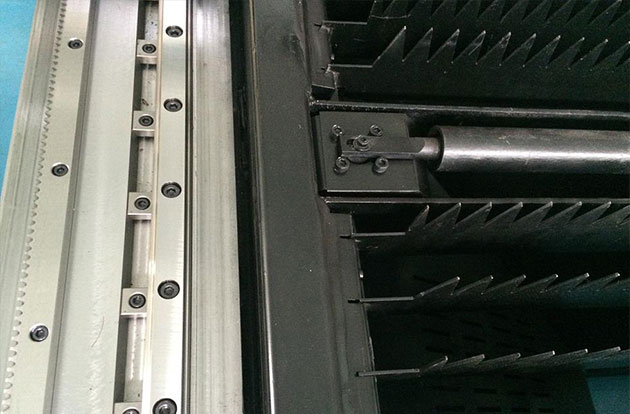

5)Workbench. The precision of the table will also directly affect the laser cutting effect.

6)Rack and pinion. HANS GS laser cutting machine drive mode on the X, Y axis selection of unilateral servo motor configuration corresponding reducer, with high precision rack and pinion drive structure; have X-axis are selected on both sides of the servo motor with the corresponding reducer, with high Precision gear rack drive structure, a double gear to eliminate the reverse gap drive mode; servo motor configuration with high precision ball screw direct drive, the use of disc-type large inertia motor direct gear, rack drive; there are linear motor direct Driven structure of the way.

7)material. Different materials have different cutting precision. Material composition is different, the cutting accuracy will be different. Therefore, the workpiece material on the laser cutting accuracy also has a certain impact.

HANS GS specializes in the production and sale of fiber laser cutting machine, 3D robot cutting machine, to provide you with the latest fiber laser cutting machine prices and parameters, Welcome to our factory.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam