Do you know the focusing function of HANS GS laser cutting machine?Laser cutting machine cutting metal sheet has an unparalleled advantage, it is not only high precision and smooth,Whether it is cutting thick plate or thin can achieve good results,However, these effects are closely related to the focus control of the laser cutting machine, just like the SLR camera's focus, to achieve a better imaging effect is a principle.

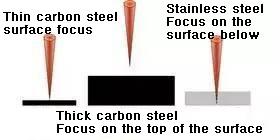

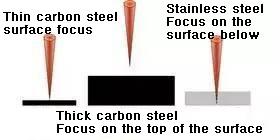

So what is the focus control? Familiar with HANS GS laser cutting machine friends know that laser cutting machine in the cutting of different materials and different thickness of the plate, in order to achieve better cutting results, the focus of the laser beam will be set in different places (pictured), known as we Said focus.

In the early application of laser cutting machine, the main way of focusing is manual, and now with the development of laser technology, this manual focus has been gradually eliminated, auto focus function has begun to slowly achieve, such as HANS GS laser cutting Machines are equipped with automatic focusing function.

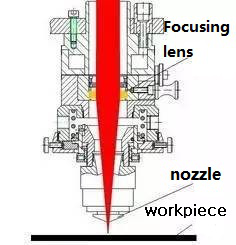

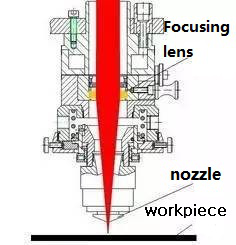

Someone will say that the optical path is integrated in the cutting head inside, by changing the height of the cutting head is not to achieve the focus function yet? The cutting head is raised, the focus position is high, the cutting head is lowered, the focal position is low. However, it turns out that it is not so simple to imagine (as shown below).

The tip of the cutting head is the nozzle. During the cutting process, the distance between the nozzle and the workpiece (nozzle height) is about 0.5 ~ 1.5mm, which may be regarded as a fixed value, that is, the nozzle height can not be changed by lifting the cutting head Coke (otherwise it can not finish cutting).

The focal length of the focusing lens is irrevocable, so it can not be expected to focus by changing the focal length. If you change the position of the focus lens, you can change the focus position: focus lens down, the focus down, focus lens rise, the focus rises. - it is a way of focusing. The use of a motor-driven focusing lens for up and down movement, you can achieve automatic focus.

Another way to focus automatically is to change the focus position by changing the curvature of the mirror and changing the divergence angle of the reflected beam before changing the curvature mirror (or tunable mirror) before the beam enters the focusing mirror. As shown below.

With automatic focus function, in the processing of different materials, different thickness of the workpiece, the machine can automatically adjust the focus to the most appropriate location. This can significantly improve the processing efficiency of laser cutting machine, thick plate piercing time will be greatly reduced.

Therefore, for laser cutting machine, auto focus function is an important and indispensable function.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam