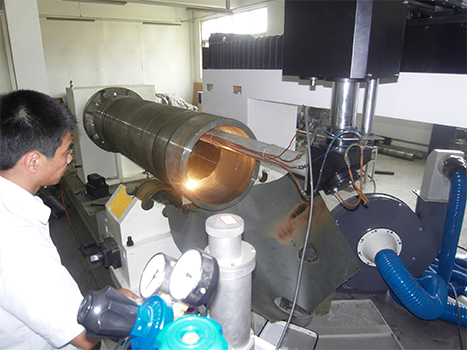

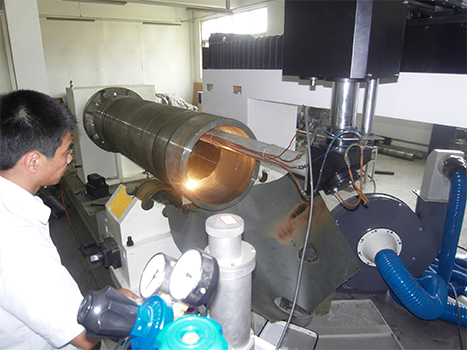

Several Typical Applications of Laser Cladding Technology

The

scope and application of laser cladding technology is very extensive

and can cover almost the entire machinery manufacturing industry,

including mining

machinery,petrochemical,power,railway,automobile,shipbuilding,metallurgy,medical

equipment,aviation,machine tools,power

generation,packaging,mold,pharmaceutical and other industries.

1.Manufacturing and re-manufacturing of mining equipment

Mine coal machine equipment, due to its poor working environment, parts damage faster:

A,

Shearer: main frame, rocker arm, gear, gear shaft, all kinds of

bushings, hinge frame, cylinder, cylinder seat, guide shoe, sprocket,

pin wheel, drive wheel, pick and so on.

B, Boring machine: cylinder, bracket, shaft, all kinds of bushings, pick and so on.

C, Scraper transport: the middle chute, transition tank, gear box, gear, gear shaft, spiral bevel gear, shaft parts.

D, Hydraulic support: cylinder, base and bracket, such as the hinge, a variety of bushings.

2.Manufacture and Re-manufacturing of Electric Power Equipment

The

distribution of power equipment is large, uninterrupted operation, the

damage rate of its parts is high. Steam turbine is the core equipment of

thermal power generation, due to the special conditions of high

temperature and high heat, every year on the need for regular damage to

the damage to the unit parts, such as spindle shaft diameter, moving

blades and so on. Gas turbines are often damaged due to their high

temperature conditions up to 1300 ° C. Using laser re-manufacturing

technology to repair all the defects intact, to restore its performance,

the cost of only the new unit price of 1/10.

3.Manufacture and Re-manufacturing of Petrochemical Equipment

Modern

petrochemical industry is basically used in a continuous mass

production mode, in the production process, the machine for a long time

in harsh environments, resulting in equipment components damage,

corrosion, wear, which often problems parts include valves Pumps,

impellers, journals for large rotors, rovers, bushings, bushings, etc.,

and these components are very expensive, there are many types of parts

involved, most of the shape is very complex, there are some difficulties

to repair, but Because of the emergence of laser cladding technology,

these problems are not a problem.

4.Manufacture and re-manufacturing of railway equipment

Railway

transportation with the rapid growth of social and economic growth, the

new rail vehicle demand is very large, the number of major parts and

performance requirements are also increasing. Re-manufacturing

technology, as a new resource reuse technology, can be applied to

re-manufacturing of easily wearable parts. The laser surface

strengthening is the core technology and technology of re-manufacturing,

in which the laser surface cladding technology can be applied to the

remodeling and repair of the surface of the re-manufactured parts.

5.Re-manufacturing of key parts of other machinery industry equipment

Other

parts of the machinery manufacturing industry, including the

metallurgical, petrochemical, mining, chemical, aviation, automotive,

shipbuilding, machine tools, etc., for these areas of precision

equipment, large equipment, precious parts wear , Erosion, corrosion

parts, the use of laser cladding processing technology to repair and

performance optimization.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam