Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Address:No.72,Optical valley Avenue, East Lake High-Tech Development Zone,Wuhan.P.C:430223

Tel:+86-27-8792 4929

Fax:+86-27-8792 4929

Whats app:+86-18717170727

Skype:sales_hansgs@outlook.com

Email:hansgs@hansgslaser.com

2016-08-29

Fiber laser cutting enter to the elevator market and promote their technological breakthrough!

Elevator is produced to follow the pace of technology, it is the indispensable convenient tool of modern society and daily life and has become a symbol of material civilization.

Driven by the development of the real estate industry and urban public construction, China's elevator market keep for 20% annual rate of increase to be the world's largest elevator market. In addition, with the new fiber laser cutting machine is widely used to metal sheet processing, fiber laser cutting technology has also been used to elevator manufacturing, and it has improved the automation, intelligent elevator industry and promoted technological breakthroughs of elevator processed.

What is the difference between the traditional processing methods and laser laser processing technology? How does the fiber laser cutting technology to push the outbreak of the elevator market?

1. Traditional processing method

The whole plant was basically a conventional multi-punch sheet metal processing for the last technical, including cars, milling, planing, drilling, grinding and other processing procedures, which rely mainly on mechanical force more rigid tools to complete the process of stripping the excess metal layer. Procedures are complicated and volatile type workpiece, consume a lot of manpower, material and financial resources.

2. CO2 laser processing method

CO2 laser cutting machine was the first laser equipment used in domestic elevator industry used. The use of optical, electrical, chemical and other non-mechanical energy to complete the stripping process material with a lower hardness material, it can realize the processing of high hardness of the material. Compared to conventional processing methods with the advantages of non-contact laser processing, easy processing, security, environmental protection and others.

3.Fiber laser processing method

Elevator manufacturers are mainly about 3mm stainless steel mainly, the gas and processing power consumption are laser using CO2 laser cutting machine. CO2 laser cutting machine can’t keep pace with the elevator industry because of its high cost, complex debugging and other shortcomings. New fiber laser cutting machine has a fast, ultra-low running costs and can cut copper, aluminum, high reflective materials, and no outside optical path, etc. Due to these significant advantages, it is gradually replace CO2 laser cutting machine to become the first choice for the elevator processing industry.

In order to meet the needs of a large number of sheet metal working elevator market. Han’s GS Laser has developed a variety of processing in line with the elevator fiber laser cutting machine with its sophisticated laser technology and research & development experience. For examples, GS-LFDS4015 large format full protective high-speed fiber laser cutting machine, it can keep fast speed while ensuring the smoothness of its cross-section.

GS-LFDS4015 large format full protective high-speed fiber laser cutting machine

Features:

1. Highly automation:

Adopts digital control, you only need to use CAD to draw the picture and import to specialized software, laser cutting machine can cut out the artifacts you need, moreover there is intelligent typesetting function, thus can save raw material costs to the greatest extent.

2. High cutting efficiency:

Due to the transmission properties of laser, laser cutting machine has equipped with many sets of CNC work bench to realize numerical control. You only need to change the CNC program to cut different shape, as well as for two-dimensional cutting, and three-dimensional cutting.

3. Fast cutting speed:

The cutting speed can be up to 600 cm/min when using 1200W laser to cut 2mm low carbon steel plate, and can up to 120 m/min when cutting 5mm polypropylene resin plate. Material does not need clamping fixed for cutting, thus can save the jig and auxiliary time for material upload and download.

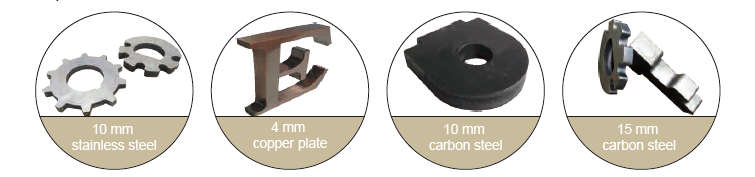

4. Variety cutting material:

Compared with oxyacetylene cutting and plasma cutting, laser can cut many kinds of materials, including metal, nonmetal, metal and nonmetal based composite material, leather, wood, fiber, etc. But for different material, it shows different laser cutting adaptability due to its thermal physical properties and different laser absorption rate.

Application