Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Address:No.72,Optical valley Avenue, East Lake High-Tech Development Zone,Wuhan.P.C:430223

Tel:+86-27-8792 4929

Fax:+86-27-8792 4929

Whats app:+86-18717170727

Skype:sales_hansgs@outlook.com

Email:hansgs@hansgslaser.com

2017-03-31

Food machinery and food intimate contact during in food production process,The quality of food machinery directly affects food safety.All the time, China's food machinery industry is facing a small and scattered, large and not the embarrassing situation, the core technology is difficult to compete with the developed countries.To be invincible in the international market,food machinery production must be mechanized, automated, specialized and large-scale, from the traditional manual labor and workshop-style operation freed, improve health, safety and production efficiency.

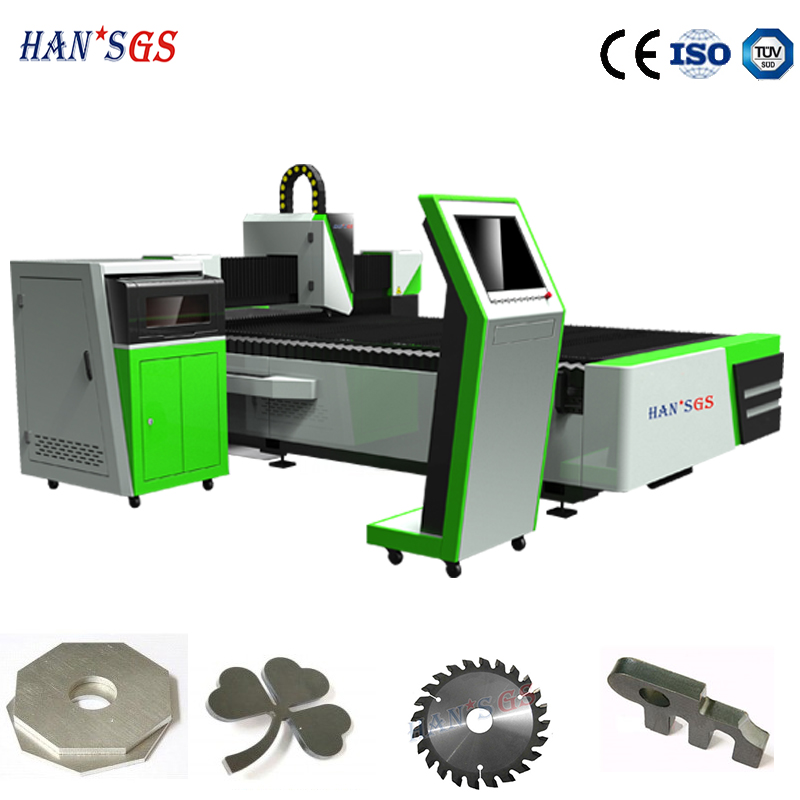

Compared with the traditional processing technology, fiber laser cutting machine in the food machinery production advantages. The traditional processing methods need to open mold, stamping, cutting plate, bending and other links, low efficiency, mold consumption, the use of high cost, seriously hindered the pace of food machinery industry innovation and development.

Laser processing in the application of food machinery has the following advantages:

1, Safety and health,laser cutting is a non-contact processing, cleaning.

2, Cutting slit fine,laser cutting of the slot is generally 0.10 ~ 0.20mm.

3, Smooth surface,laser can cut a variety of thickness of the plate, and the truncated surface is very smooth, a molding, build high-end food machinery.

4, fast, and effectively improve the efficiency of food machinery production.

5, Suitable for large-scale processing of products, large pieces of mold manufacturing costs are high, laser cutting without any mold manufacturing, and can completely avoid the formation of the material when the collapse of the pile, a significant reduction in production costs, improve food machinery Of the grade.

6, Suitable for the development of new products,Once the product drawings are formed, you can immediately laser processing, in the shortest possible time to get the new product of the kind.

7, Saving materials, laser processing using computer programming, can maximize the utilization of materials, reduce food production costs.