From early Big Brothers to today's smart phones, mobile phones have evolved from 2G, 3G to 4G era, and will soon develop and produce mobile phones in the 5G era.

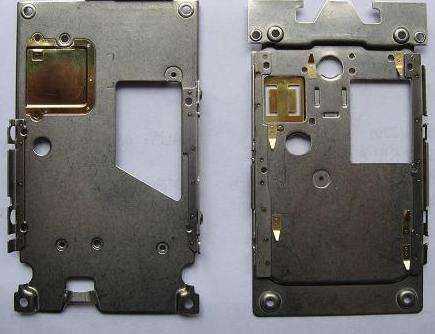

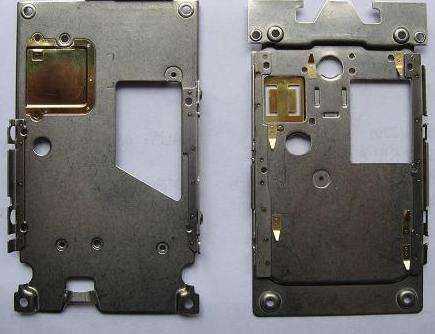

Now mobile phone manufacturers will develop their mobile phones in a light and thin direction, their internal components will become smaller and smaller, precision and electronic integration will become higher and higher, and the requirements for internal component welding technology will also increase.

For the micro parts in the mobile phone, the welding quality of the traditional welding technology is not stable, which easily leads to melting of the parts, difficulty in forming a normal nugget, and low welding yield. The advent of laser welding technology has solved these problems for manufacturers of electronic products.

The laser beam is non-contact processing, with low thermal impact, small processing area, and flexible methods. In the current production process of high-end mobile phones, laser welding machine technology has played a major role in the volume optimization and quality improvement of products, making the products more lightweight, lighter and more stable.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam