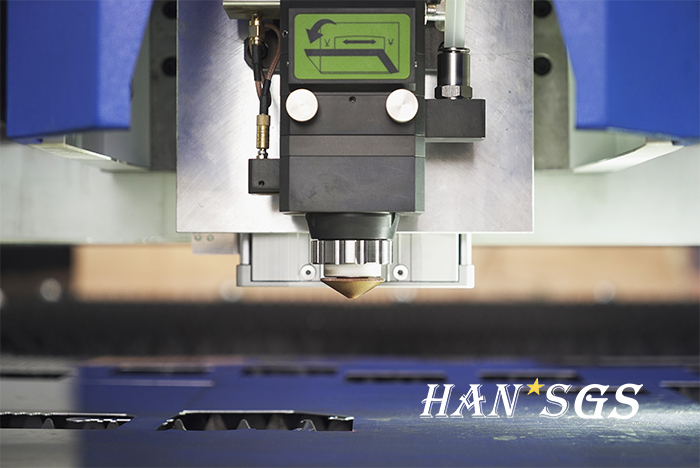

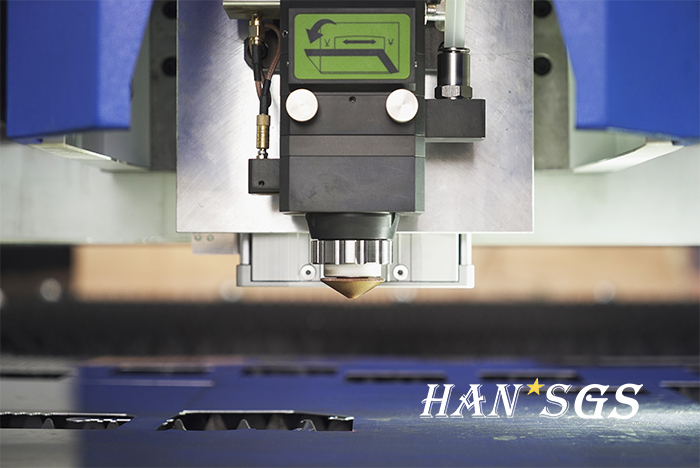

In the laser cutting machine for parts with high cutting accuracy or thickness, several key technologies must be mastered and solved. Focus position control technology is one of them. One of the advantages of laser cutting is that the energy density of the beam is high, so the focal spot diameter is as small as possible to produce a narrow slit. Because the focal depth of the focusing lens is smaller, the focal spot diameter is smaller. For high quality cutting, the effective depth of focus is also related to the lens diameter and the material to be cut. Therefore, it is important to control the position of the focal point relative to the surface of the material being cut.

How to use a laser cutter to cut high quality products? The focus is very important!

Since the laser power density has a great influence on the cutting speed, the choice of lens focal length is an important issue. After the laser beam is focused, the spot size is proportional to the focal length of the lens. After the beam is focused by the short focal length lens, the spot size is very small, and the power density at the focal point is very high, which is favorable for material cutting; however, its disadvantage is that the focal depth is very short and the adjustment margin is short. Small, generally suitable for high speed cutting thin materials. Because the telephoto long lens has a wide depth of focus, as long as it has sufficient power density, it is more suitable for cutting thick workpieces.

After determining which focal length lens to use, the relative position of the focal point to the surface of the workpiece is particularly important for ensuring cutting quality. Due to the highest power density at the focal point, in most cases, the focus position is just on the surface of the workpiece when cutting, or slightly below the surface. In the whole cutting process, ensuring the relative position of the focal point and the workpiece is an important condition for obtaining a stable cutting quality. Sometimes, the focal length changes due to heating due to poor cooling during lens operation, which requires timely adjustment of the focus position.

How to use a laser cutter to cut high quality products? The focus is very important!

When the focus is in the best position, the kerf is the smallest and the efficiency is the highest, and the best cutting speed can obtain the best cutting result. In most applications, the beam focus is adjusted just below the nozzle. The distance between the nozzle and the workpiece surface is generally about 1.5mm.

In the laser application process, problems such as focusing are often encountered. There are three common methods for determining the focus position:

(1) Printing method: The cutting head is moved from the top to the bottom, laser beam printing is performed on a plastic plate, and the spot where the diameter is the smallest is focused.

(2) Inclined plate method: Pull the plate horizontally at an angle to the vertical axis to pull it horizontally to find the focal point of the laser beam.

(3) Blue spark method: Remove the nozzle, blow the air, and place the pulsed laser on the stainless steel plate so that the cutting head moves from top to bottom until the blue spark is at the maximum point.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam