Gears are the foundation of the manufacturing industry and have a wide range of applications in the entire machinery industry, covering automotive, aerospace and other important industries. At the end of the “Twelfth Five-Year Plan” period, the income of the gear industry has exceeded RMB 260 billion. According to the assessment of the demand potential of downstream enterprises in the gear industry, the gear industry will have even greater room for development in the coming decades. For example, in automobile production and manufacturing, the number of newly-added automobiles in China has exceeded 23 million vehicles/year in recent years. The number of gears used in each vehicle is 18-32, and the gear transmission directly affects the stability and noise of automobiles. The performance in many aspects is an extremely important basic transmission component. Therefore, the quality and production efficiency of the gear largely affect the development of the national economy.

With the development of laser technology, more and more gear welding processes use laser technology to obtain higher welding quality. In order to meet the increasingly complex structural requirements, gears are usually used in assembled form. For assembly gear units welded by multiple gears, the current laser welding process in China is roughly artificial feeding—manual assembly—manual inspection and Handling—laser welding, where labor is the output of the main workforce, and the degree of automation is low, which limits the production efficiency of gears and cannot reduce manufacturing costs. At the same time, due to the large number of accidental factors, the consistency of the quality of gears cannot be well guaranteed. To a certain extent, it has limited the development of China's automobile and even the entire mobile industry.

Prior to this, the complete set of gear assembly and welding automation production lines owned by the country completely relied on imports. The Ministry of Industry had complete sets of automated production lines with independent intellectual property rights. Wuhan Hans Goldensky Laser System Co., Ltd. combined with market development, after researching a number of companies, developed a complete gear assembly welding automated production line, which fills the gap in the domestic production line of gear welding applications.

1.Adopt 2KW Rofin/ 2KW IPG fiber laser source.

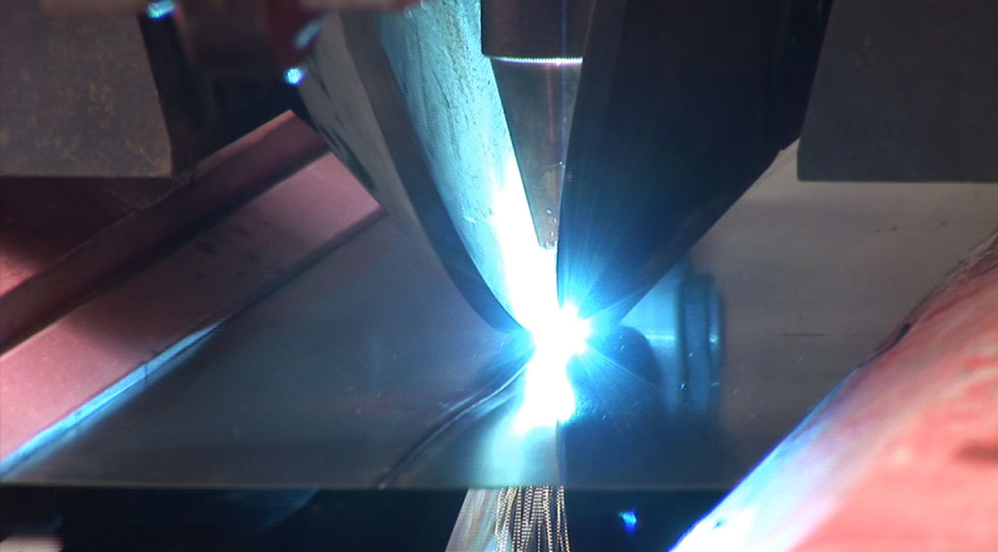

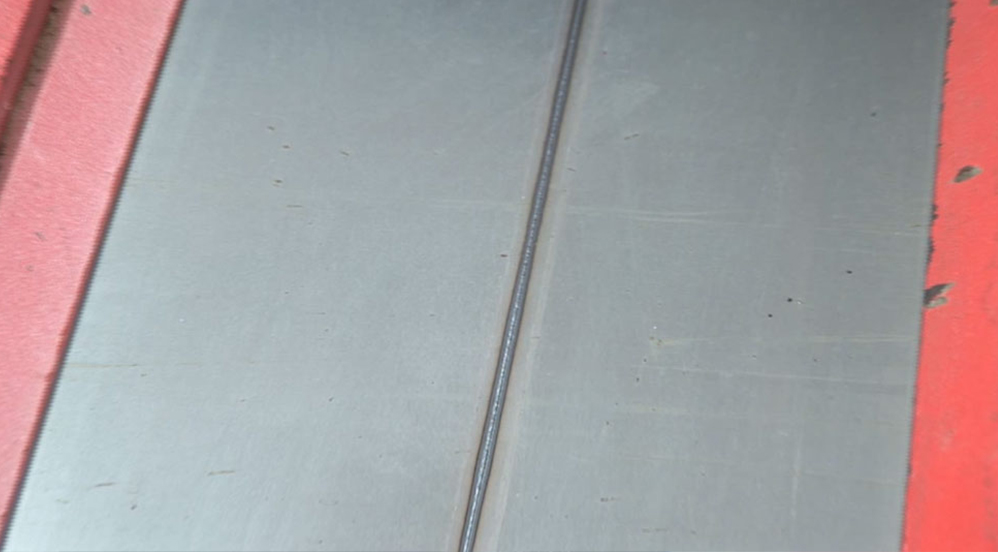

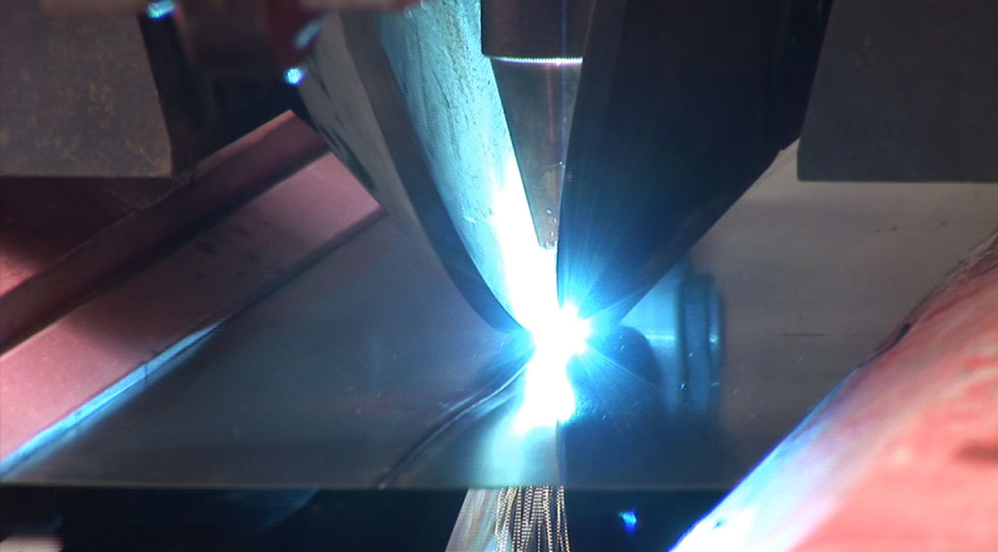

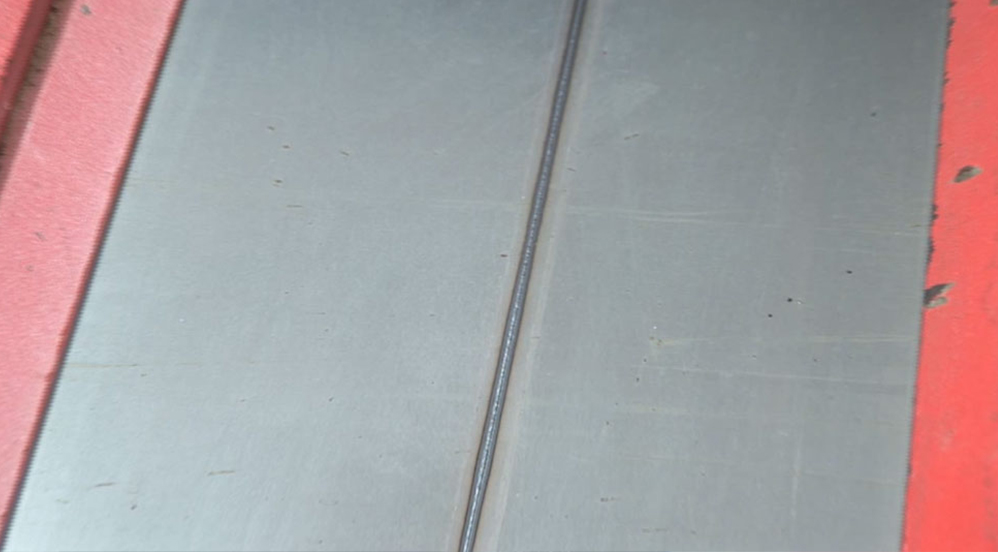

2.Flat stitch welding are two flat stacking clamp, welding as required drawing to make two tablets joined together, forming a closed cavity can reaches enough welding strength and tightness of weld (no air leakage). Shell structure workpiece can be get via expansion.

3.Workbench

Thickness of 1.2mm two pieces of stainless steel plates to be welded together on 3000*1500mm working table,forming via inflation, for the production of refrigeration equipment.

Our welding table combined with the machine can achieve the following features:

1.Adopt Linear Guide and rack automatic walk to realize entire format and positioning.

2. Driving by real automatic digital control servo motor, can be accurate positioning,simple programming and easy to control.

3. Pressure plate on a skateboard and machine tool Crossbeam alternate walking or linkage can be achieved.

4. Cylinder, automatic clamping and alternating movement regulation.

5. Bi-directional drivers, ensures the synchronization of both ends of the clamping.

6. Compacting the size of the area can be adjusted, can improve the clamping effect.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam