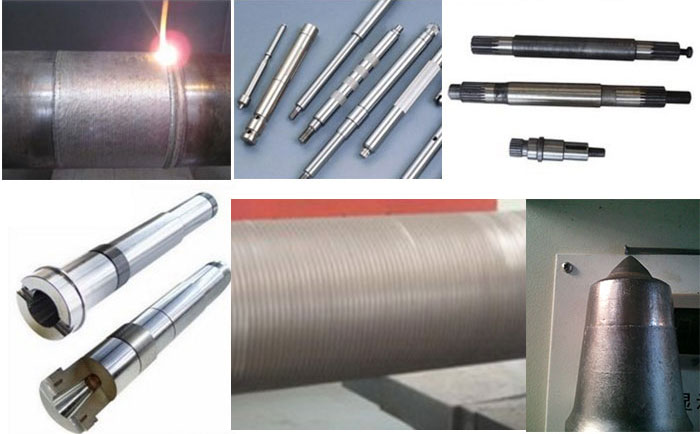

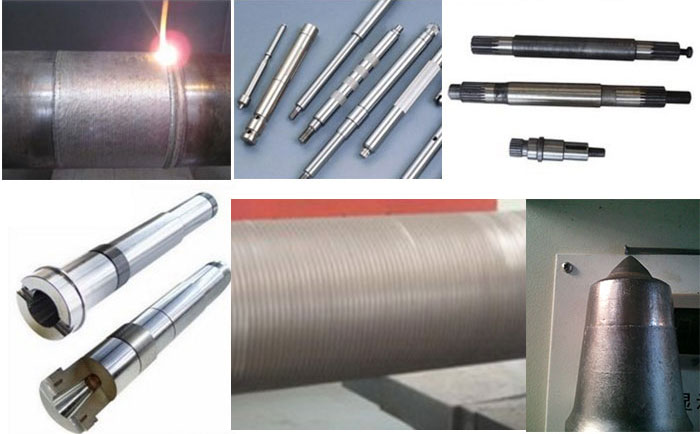

With the development of the processing industry, the processing forms are also changing. The laser heat treatment technology uses a high-power laser laser to heat the surface of metal materials. Because the power density is extremely high, the heat of the processed product surface cannot be transferred in time. The processing area on the surface of the processed article under high temperature rapidly heats up to the austenitizing temperature to achieve rapid heating. Because the processing is very rapid, the overall temperature of the processed article is still kept at a low temperature, and the instantaneous high temperature generated in the processing zone is diluted by the overall temperature of the object, thereby achieving the effect of heat treatment such as quenching. Low-power laser lasers rapidly oxidize or vaporize surface materials to achieve the effect of marking. This is what fiber laser marking machines use today, and thus has been widely used in many fields. This technology is mainly used to strengthen the surface of auto parts or tooling, improve its surface hardness, wear resistance, corrosion resistance and strength and high temperature performance, such as automotive engine cylinder bore, crankshaft, stamping die, casting plate, etc. Laser heat treatment.

With the development of high-power lasers, the form of laser heat treatment is becoming more and more diversified. In the processing time range of 10-3s to 10-7s, the power density is greater than 0.1 kW per square millimeter, causing the surface structure of the material. Changes to achieve heat treatment of the processed item list. The application is very extensive, and it can realize the heat treatment on almost all the metal surfaces. Now it has a wide range of applications in automobiles, metallurgy, heavy machinery, hardware products, ships, medical equipment, aviation and aerospace.

Laser processing is a transformation and upgrading of traditional processes. The excellent performance of lasers is impacting more and more traditional industries, providing a more efficient and efficient processing solution for many industries. The laser heat treatment technology utilizes a high-power laser, combined with current automation technology, and computer control technology to process processed articles. The high-power laser beam is under the control of a computer and the heat treatment of industrial parts is realized through the automation technology. Compared with the traditional processing method, the laser heat treatment technology has a high concentration of energy, a small processing area, and thus a small thermal distortion, high processing quality and precision. High, processing parts are not limited by size, shape, no cooling media, and no pollution, low noise, high efficiency.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam