Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Address:No.72,Optical valley Avenue, East Lake High-Tech Development Zone,Wuhan.P.C:430223

Tel:+86-27-8792 4929

Fax:+86-27-8792 4929

Whats app:+86-18717170727

Skype:sales_hansgs@outlook.com

Email:hansgs@hansgslaser.com

2018-03-13

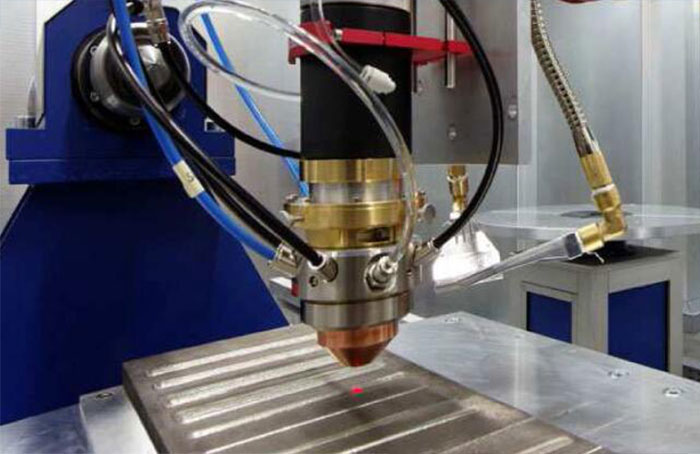

HANS GS found that the different scanning speed had a significant

effect on the quality of the cladding layer. The suitable scanning speed

made the cladding layer continuous, smooth, smooth and without pores.

The faster scanning speed led to the discontinuity of the cladding

layer, and the intermittent bead and void.

Other factors that affect the quality of the laser cladding

layer of exhaust valve include the pressure of the protective gas. The

experiment found that the excessive pressure of the protective gas will

make the surface roughness increase, and the surface is uneven and

smooth, resulting in wrinkle. The pressure of protective gas is too

small. First, the surface of cladding layer can not reach the purpose of

preventing oxidation. It will make the oxygen in air participate in the

action of laser and powder and cause the defect of cladding layer.

The

pollution of the lens will also have an impact. Because the beam and

the protective gas coaxial, not only to protect the role of the molten

pool, but also to protect the role of the lens. In the process of laser

treatment, splashing is unavoidable. Shielding gas can prevent slag from

flying to the focus lens. Therefore, the pressure of protective gas can

not be ignored.

The pollution of the lens will also have an impact.

Because the beam and the protective gas coaxial, not only to protect the

role of the molten pool, but also to protect the role of the lens. In

the process of laser treatment, splashing is unavoidable. Shielding gas

can prevent slag from flying to the focus lens. Therefore, the pressure

of protective gas can not be ignored.

Fixture is an important factor

affecting the quality of cladding layer. In the laser cladding process,

fixture must ensure that the exhaust valve can rotate at a uniform

speed, so that the scanning speed is constant. The position of beam

irradiation coincides with the position of the slotting, otherwise the

cladding layer will deviate and cause the workpiece to be scrapped.

(1)

In the exhaust valve pre coating process, when the laser power, spot

diameter and scanning speed are constant, the coating thickness is 1mm

to 2mm, and the alloying ratio of the alloy powder to the adhesive is

2%. The ideal surface quality of laser cladding can be obtained.

(2)

The best process parameters of laser cladding of automobile exhaust

valve are: laser power 1.8kW to 2.1kW, spot diameter 4.5mm to 5mm,

scanning speed 5mm/s to 6mm/s., cladding layer continuous, smooth and

smooth, basically no pores, stable process, and can be used for

industrial production.