Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Address:No.72,Optical valley Avenue, East Lake High-Tech Development Zone,Wuhan.P.C:430223

Tel:+86-27-8792 4929

Fax:+86-27-8792 4929

Whats app:+86-18717170727

Skype:sales_hansgs@outlook.com

Email:hansgs@hansgslaser.com

2017-11-21

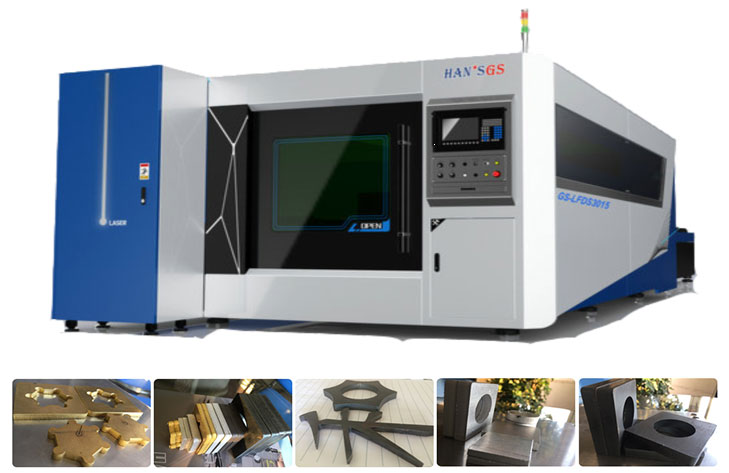

High Quality Tool For Metal Processing HANS GS Laser Cutting Machine

Carbon steel, stainless steel, aluminum and other metals belong to a kind of alloy steel, it is not only widely used in buildings, bridges, railways, vehicles, ships and machinery manufacturing industry, but also in the modern petrochemical industry, marine development and so on, have also been widely used. In the life, the surface carbon steel is also widely used because of its excellent texture.

With carbon steel as an example, the application of carbon steel is more and more widely, but in the traditional carbon steel processing process, due to the lack of equipment, the carbon steel after processing appeared scarring, cracks, delamination, white spots, impurities, loose and so on. Therefore, the metal laser cutting machine has become the first choice in the carbon steel processing.

Laser cutting of carbon steel, laser source emitting laser irradiation, in the surface layer of carbon steel, high temperature generated by the auxiliary gas under the action of fast and carbon steel contains silicon, manganese, sulfur, phosphorus and other elements in the oxidation reaction, melting and vaporization, can penetrate the steel, and then through the control of laser to achieve the purpose of cutting displacement numerical control.

Because carbon steel contains carbon, light reflection is not strong, the absorption of light beam is very good, carbon steel in all metal materials is the most suitable for laser cutting machine processing, but also the best effect.

For carbon steel, laser cutting machine has the advantages of laser cutting richly endowed by nature, fast speed, high cutting precision, can meet the requirements of all sheet metal processing, and the cutting surface smooth, beautiful appearance, convenient use, safety, cost saving, which is any machining incomparable.

As an advanced manufacturer of laser equipment in our country, HANS GS laser has been used for many years in the field of laser cutting machine, especially high-power laser cutting machine, and has contributed a lot of high-quality products for the metal processing market. HANS GS-LFDS3015 CNC optical fiber laser cutting machine, using imported laser, with outstanding quality, speed lightning service, let the metal processing industry experience "China made" strength.

Functions of GS-LFDS3015 Laser Cutting Machine

▪Excellent overall performance, changeable working tables, 7 seconds to finish high speed changing, improve working efficiency of more than 48%.

▪The machine tool includes loading area and processing area, standard configuration is changeable working tables, auto change the workpiece between processing area and loading area by motor, convenient to upload and download. With the design of changeable working table, could prepare the next uploading while processing, highly improved working efficiency.

▪Equipped with exhaust device, have good exhausting effect and little pollution.

Small occupied area, high system integration, convenient to operate and maintenance,24 hours continuous working.

▪The water chiller has good safety protection function, such as over temperature, lack phase, pressure, water-break, undervoltage, overload, etc. With stable performance, satisfied the cooling requirement of laser source.