Laser Marking/Cutting/Cladding/Perforating/Welding Machine Manufacturer-HANS GS LASER

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Language

Language

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

Address:No.72,Optical valley Avenue, East Lake High-Tech Development Zone,Wuhan.P.C:430223

Tel:+86-27-8792 4929

Fax:+86-27-8792 4929

Whats app:+86-18717170727

Skype:sales_hansgs@outlook.com

Email:hansgs@hansgslaser.com

2017-10-17

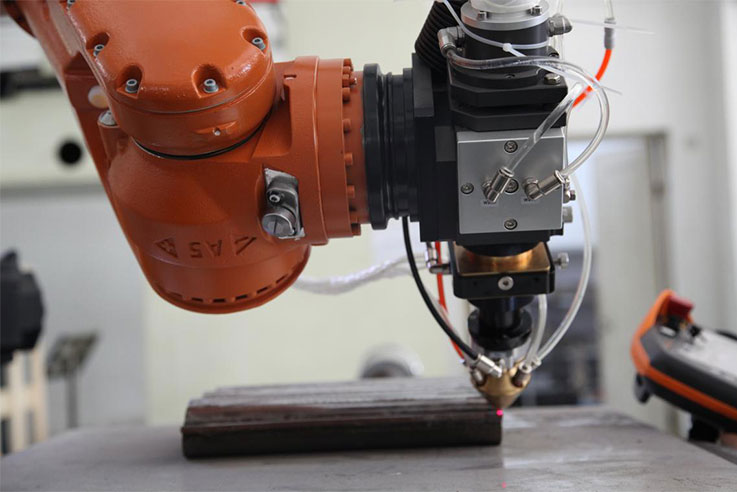

LASER CLADDING REMANUFACTURING IS A MAGIC TOOL FOR DECAY  Laser cladding (Laser cladding) is in a different way in the feed was placed on the surface of the laser cladding coating material is selected after laser irradiation and a thin layer of the substrate surface and melting, rapid solidification and formation dilution is very low, the surface coating of a metallurgical bonding with the substrate. The process of wear resistance, corrosion resistance, heat resistance, oxidation resistance and electrical properties of the base surface is improved remarkably, so as to achieve the purpose of surface modification or repair, and realize the repair and remanufacturing.

Laser cladding (Laser cladding) is in a different way in the feed was placed on the surface of the laser cladding coating material is selected after laser irradiation and a thin layer of the substrate surface and melting, rapid solidification and formation dilution is very low, the surface coating of a metallurgical bonding with the substrate. The process of wear resistance, corrosion resistance, heat resistance, oxidation resistance and electrical properties of the base surface is improved remarkably, so as to achieve the purpose of surface modification or repair, and realize the repair and remanufacturing.

It has the characteristics of small dilution, compact structure, good combination of coating and substrate, large particle size and content change, minimum deformation and the most shallow heat affected zone, and automatic two-dimensional or three-dimensional metal deposition. Laser remanufacturing, with renewed vitality HNAS GS old parts remanufacturing engineering is a high-energy laser technology, advanced numerical control technology, computer technology, CAD/CAM technology, robotics, advanced materials technology and photoelectric detection technology, based on the product life cycle design and management as a guide, with high quality, high efficiency and energy saving and material saving and environmental protection as the goal, with advanced technology and industrialization as a means to repair or reconstruction of the failure of a series of technical measures and engineering activities, not only can make the parts failure to return to the original size, and the performance to meet or exceed the original level of base material.

The reason of laser remanufacturing is that the objects can be repaired by laser cladding, such as plane, curved surface and 3D solid. It can complete the repair of flange sealing surface, blade surface strengthening, shaft parts wear, turbocharger rotor bearing position and so on. Widely used in industrial mold, ore, metallurgy, military industry, nuclear power, ships and rail transportation and other fields.