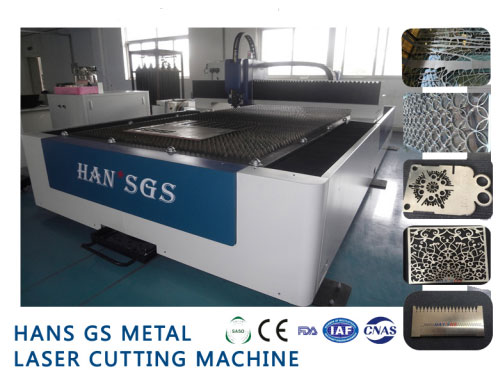

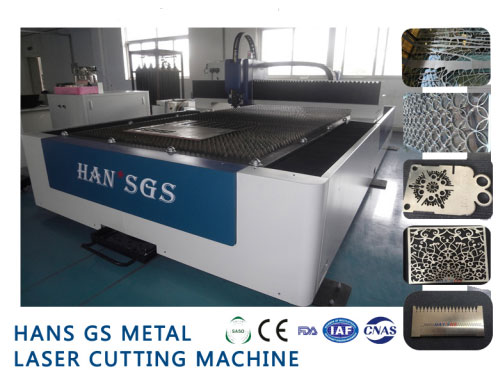

How to choose the auxiliary gas of the laser cutting machine?

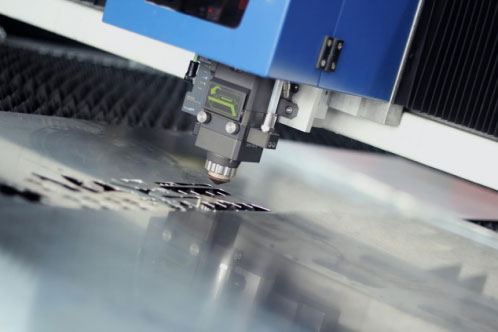

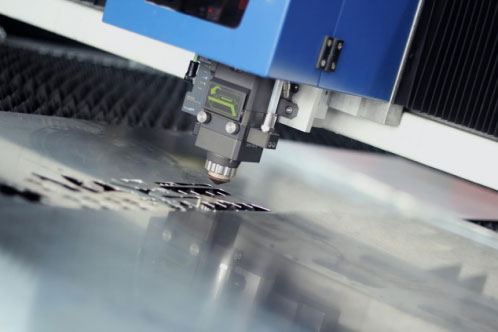

Laser cutting machine must be added in the process of auxiliary gas, auxiliary gas can blow away the slit within the coaxial slag, but also cooling the surface of the object, reduce the heat affected area, cooling the focus lens to prevent dust into the lens seat pollution Lens and lead to lens overheating. So the choice of auxiliary gas is a great knowledge.

At present, the laser cutting machine can use the auxiliary gas mainly oxygen, nitrogen, air and argon, the following we for different auxiliary gas, to show you about the characteristics.

1, Oxygen

Mainly used for laser cutting machine cutting carbon steel. The use of oxygen reaction heat to improve the efficiency of large-scale cutting at the same time, the resulting oxide film will increase the reflection of the beam spectral absorption factor. The cut face is black or dark yellow.

Mainly applicable to rolling steel, laminated structure with rolling steel, mechanical structure with carbon steel, high tension version, tool plate, stainless steel, electroplated steel, copper, copper alloy.

2, Nitrogen

Some of the metal in the cutting when the use of oxygen in the cutting surface will form an oxide film, the use of nitrogen can be carried out to prevent oxidation of oxide film cutting. No oxidation cutting surface can be directly welded, smear, corrosion resistance and so on. Cut the end face white.

Mainly applicable to the plate are stainless steel, galvanized steel, brass, aluminum, aluminum and so on.

3, Air

The air can be supplied directly from the air compressor, so the price is very cheap compared to other gases. Although the air contains about 20% of the oxygen, but the cutting efficiency is far less than oxygen, cutting capacity and nitrogen similar. Cutting surface will appear trace oxide film, but can be used as a measure to prevent the coating layer off. The cut face is yellow.

Mainly applicable materials are aluminum, aluminum, stainless steel, brass, plated steel, non-metallic, and so on.

4, Argon

Argon is an inert gas, used in laser cutting machine cutting to prevent oxidation and nitriding, also used in welding, compared with other processing gases, the price of japonica, the corresponding increase in costs. Cut the end face white.

The main application of the material is titanium, titanium and so on.

The choice of gas pressure and type has a great influence on the cutting process. The choice of auxiliary gas will have some influence on the cutting performance, including cutting speed and cutting thickness.

In daily use, because the air price is relatively cheap, widely used for carbon steel, stainless steel and aluminum, can also be used to cut copper, galvanized sheet and other materials. Of course, air cutting is not no shortcomings, air compressor and cold and dry machine on time and maintenance, to ensure that the air quality clean water without oil. If you do not pay attention to these may cause air unclean water containing oil, unclean air into the cutting head will first pollute the protective mirror to affect the cutting quality, if not dealt with in time may also damage the sensor. Equipment that does not have a pressurized device installed, subject to pressure limits The cutting thickness and cutting speed are limited. In addition, the small and medium-power fiber laser cutting machine using air cutting on the cutting speed to enhance the effect is not, high-power fiber lasers will be more advantages.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam