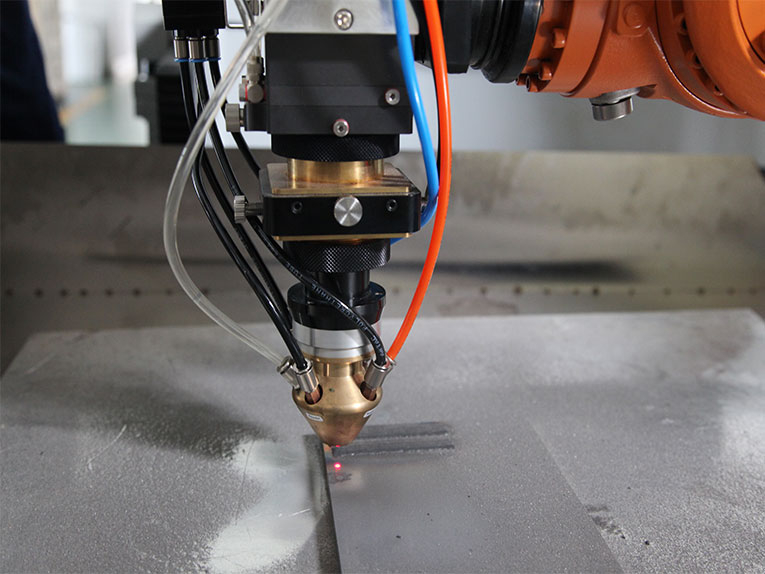

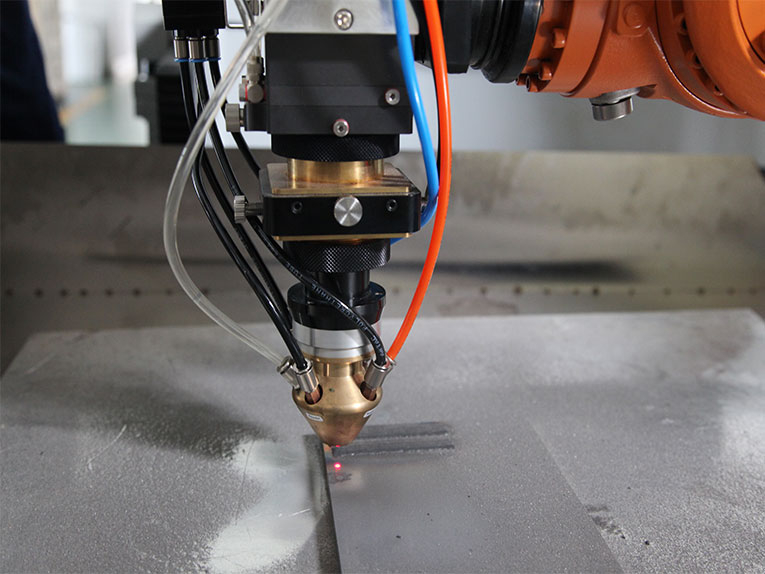

Laser welding is an advanced welding technology in industrial production, from the beginning of 1980s, with the kilowatt laser technology, laser welding has gradually extended, now widely used in laser welding technology of high precision manufacturing.Laser welding is an efficient and precise welding method which uses high energy density laser beam as heat source. Compared with traditional spot welding, laser welding has many advantages and can greatly enhance the performance of all aspects of automobile.

In the industry, laser welding has become another generation of reliable and safe car products. At present, domestic automobile such as BYD, FAW's top cover, back door and other important areas of the body have used laser welding technology.

Advantages of HANS GS laser welding equipment:

Welding quality is better, laser welding using hot-melt welding filler gap technology, after welding, the body sheet metal material overall fit, welding surface smooth integration, the overall welding quality is excellent. Although the ordinary welding spot welding of low cost, but there are potential welding defects after welding, welding, welding bubble bag surface porosity.

The welding speed is fast, the welding speed of laser welding is 5~6 meters per minute, and the speed of spot welding is 1 /3 seconds on average. Take the top cover of automobile as an example, about 100 solder joints need to be welded. For example, welding with single spot welding will take 5 minutes. For laser welding, laser welding head and welding zone of a single 4 meters long, takes only 0.8 minutes.

Good sealing effect. The laser welding method is line welding, the welded body sheet metal region is integrally welded and completely sealed, which perfectly solves the sealing requirements that the body can not leak or leak. For the non continuous welding spot welding, solder joint between the distance exists inevitably, the overlapping region between solder joints may exist gap, in order to meet the body can not Water Leakage and air sealing requirements must be achieved by the auxiliary sealant.

The strength of the laser welding part is higher. Through tensile test, it can be found that the force needed to crack the 1 joints will be about 3500. The laser welding will form 1.5 times the strength of the welding seam of the same length.

The design of laser welding of the weld edge is short, can effectively reduce body weight: laser lap welding design edge zero fit design only considers the sheet metal stamping process can be suitable for spot welding material; overlapping edge design at the same time of joint space. Depending on the width of the plate thickness, usually around 16 mm, the longer side of the material means that the weight of the body is more heavy.

The appearance of welding is more beautiful: the final appearance formed by laser welding, the lines are smooth and tidy, and the whole has texture. The appearance of the spot welding is uneven and has inherent defects such as welding pits, edges and corners, burrs and so on. It is usually necessary to add decorative strips for shielding.

As a high technology welding technology, laser welding will give priority to areas that apply to the body appearance area, because the body appearance area requires high welding quality. In these areas, if the welding is selected and the welding space is limited, the process layout will be very complex, which will result in poor welding quality and can not meet the expected quality effect of the design.

The wide range application of laser welding can not only indicate the beauty of the car and improve the production efficiency, but also can effectively improve the stiffness of the whole vehicle, thereby enhancing the safety of the car.

With the development of technology, laser welding is no longer exclusive to some joint venture brand "God car". Based on the consideration of product quality improvement, the major automobile factories in China are upgrading the related production equipment, and laser welding technology will be widely used. The quality and application of HANS GS will gradually promote and perfect the laser welding equipment, in the automotive side shell plate and side flow flume laser brazing technology, four door panel laser welding technology and laser welding technology research and development, will be put into production in the near future.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam