Special Measures for Optimum Quality of Laser Welding Aluminum Alloy

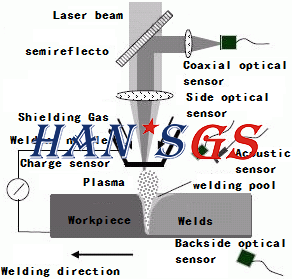

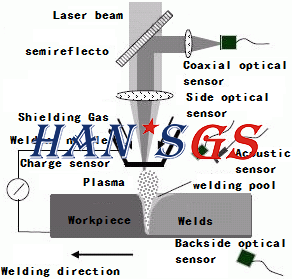

At the beginning aluminum alloy laser welding, there is a high reflection phenomenon, seriously affect the material absorption of laser energy. Wavelength is short, the material absorption of light better, therefore, Fiber laser is better than CO2 laser in absorption of aluminum alloy. Fiber laser beam mode will be better than CO2 laser, energy density is more concentrated.Once the material begins to absorb light energy, the reflectivity of the liquid metal towards the light drops markedly.

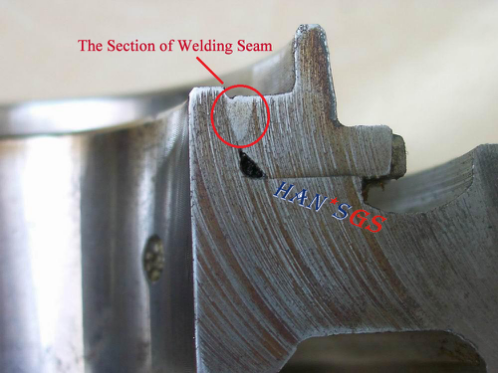

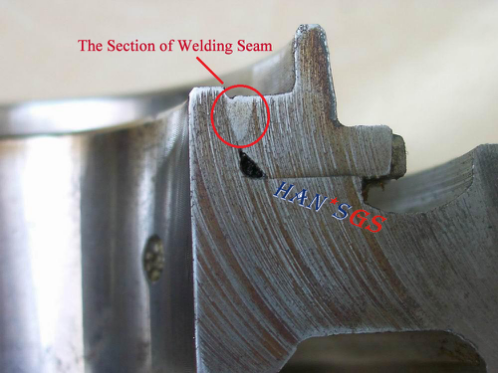

Using dual spot laser welding, can significantly improve the porosity, because of the dual beam welding, light beams form a relatively large keyhole, improves the stability of the keyhole, favors escape of the gas; compared to the serial parallel double beam, dual beam welding, molten pool temperature gradient the smaller, lower liquid metal solidification rate, prolong the bubble escape time, reduce the porosity; parallel dual beam laser welding can improve the stability of wire feeding, stable welding quality advantage.

The advantage of laser welding

(1) can reduce the amount of heat input to the minimum. The range of heat affected zone is small, and the deformation caused by heat transfer is also the lowest.

(2) the welding process parameters of 32mm thick plate and single channel welding have been certified, which can reduce the time required for heavy plate welding and even avoid the use of filler metal.

(3) there is no need to use electrodes, no electrode pollution or damage concerns. And because it does not belong to the contact type welding process, the loss and deformation of the machines and tools can be minimized.

(4) laser beam focusing, easy alignment and by optical instrument guide, can be placed in the appropriate distance from the workpiece, and can guide in the equipment or the obstacles around the work piece, and other welding rules can not play due to the limited space.

(5) the workpiece can be placed in enclosed space (controlled by vacuum or internal gas environment).

(6) the laser beam can be focused in a small area and can be welded with small and close spaced components.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam