HANS GS Laser Perforating &Laser cladding SOLUTIONS

Laser Perforating

Laser perforating is a process of generating a series of small through holes helpful for either creating an easy-open tear path or modified atmosphere packaging.

● Target:Cigarette tipping paper,plastic film;

● The operation is very simple, The touch screen works with PLC to set and show the relative parameters, the faults causes and solutions as well as on-line assistance etc.;

● Operator has automatic control of hole size, number of holes, as well as down web location and spacing using laser system software;

● Flexibility to make round or elongated holes;

● Multiple lanes of holes can be produced simultaneously;

● Eliminates downtime due to tool changes or punch breakage;

● Laser beam as a tool has no physical contact with the material;

● Focused spots as small as 0.0035” (0.09mm) in diameter routinely drilled in production;

● Useful product from beginning operation to end including ramp-up and ramp-down;

● Efficient utilization of laser power;

● Wide range of materials can be processed;

● Clean micro-perforation holes - Heat energy seals the edge of the holes making them stronger. No slugs remain on the film;

● Enhanced shelf life -Micro-perforations help achieve airflow and moisture release to maintain freshness of produce;

● Easier filling / no spillage - Air is removed quickly during filling. Micro-perforations allow air to escape while containing product. Packages are more compressed and stack better;

● Reduced shipping costs - More packages compress to fit a container. Shipping load is more stable;

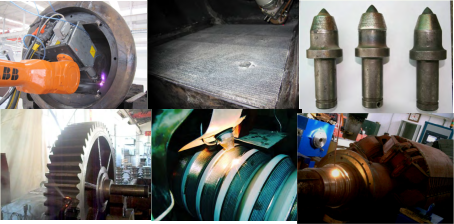

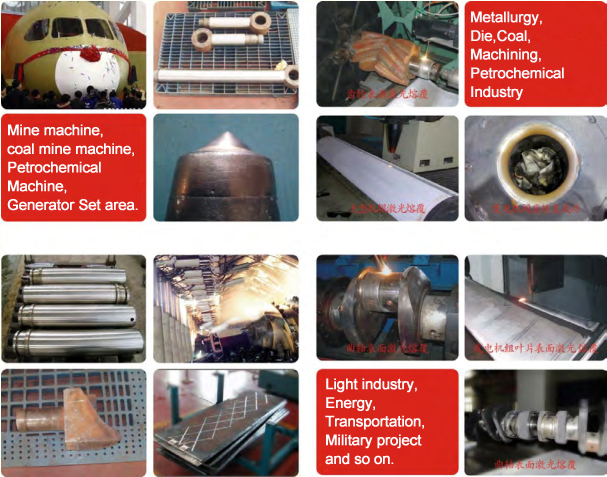

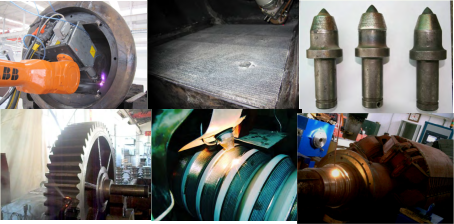

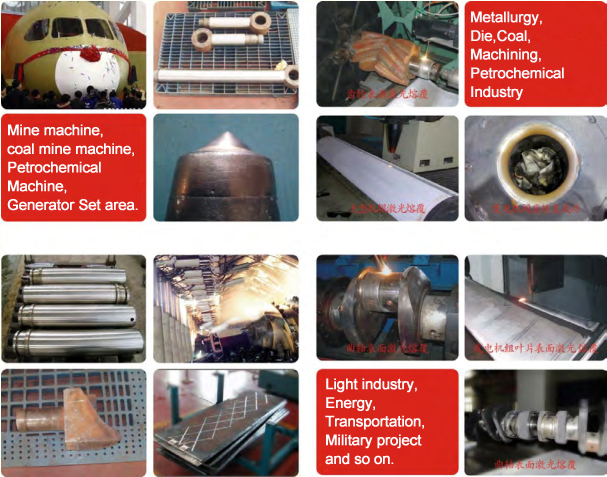

Laser cladding(re-manufacturing) for metal mechanical parts

● Target:Metallurgy,Die,Coal,Machining,Petrochemical Industry,light industry,Energy, Transportation, Military project and so on. It can be used for hardening and cladding in mobile die, Mine machine, coal mine machine, Petrochemical Machine, Generator Set area.

● Laser cladding with high energy laser beam in workpiece surface melting preset or synchronized to the surface of metal powder, the powder metallurgical bonding with parts. To restore the size of the parts, and increasing improvement of the surface of the parts performance and the purpose of rapid manufacturing deformed parts.

● High density, less mirco defect, high bonding strength,better performance;

● Accuracy to control the size and position, cladding layer width of single laser can be up to 20-30mm,Max.thickness of single layer can be up to 3mm.

● No need to preheat, simple technique progress.

● No pollution, no radiation, low noise.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam