How much do you know about laser applications in China's "C919" big plane?

C919 is China's first in accordance with the latest international airworthiness standards,It is a trunk line civil aircraft that is developed and assembled in cooperation with the United States, France and other enterprises to develop cooperative assembly.Started in 2008, at 5:10 pm on May 5, 2017, C919 was successfully taken off at the fourth runway at Pudong Airport.

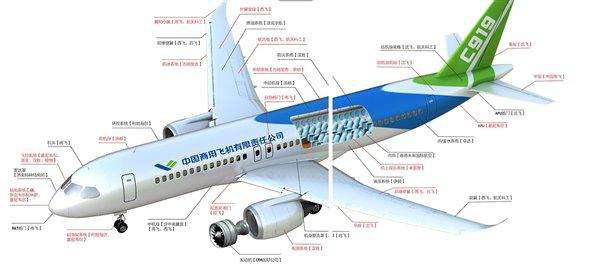

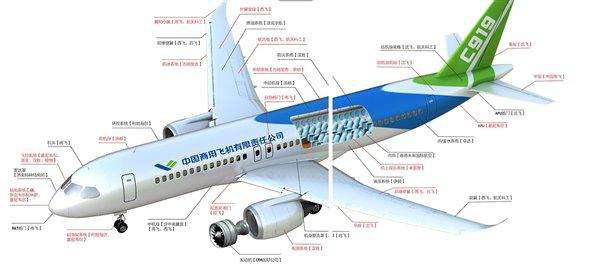

C919 structure diagram

The basic type of mixed level layout of 155 seats, the economy class layout 169, high-density layout 175, the standard range of 4075 kilometers, the maximum range of 5555 kilometers.Advanced materials for the first time in the domestic civil aircraft large-scale applications, third generation aluminum lithium alloy materials, advanced composite materials in dosage of C919 body structure were respectively 8.8% and 12%.In the future, it will compete with the Airbus 320 Series and the Boeing 737 series for international famous commercial aircraft.After nearly 10 years of hardships, Chinese of "large aircraft" the dream will become reality.Today let's talk about laser applications in space manufacturing.

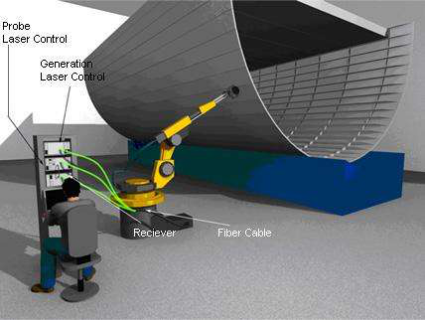

Laser cutting and drilling

In aviation manufacturing industry, laser cutting technology is mainly used for cutting special aviation materials, such as titanium alloy, Aluminum Alloy, nickel alloy, chromium alloy, stainless steel, beryllium oxide, composite materials, plastic, ceramic and quartz etc.. Aerospace parts with laser cutting of the engine flame tube, titanium alloy thin-walled casing, plane frame, titanium skin, long tail, wing truss panel, helicopter rotor, space shuttle ceramic tiles etc..

Compared with the traditional method of cutting, laser cutting technology of high precision, strong adaptability, low noise, good cutting quality for large area is used, at the same time, for some complex and complete with large abrasive machining operations, the application of laser cutting technology, not only does not require the use of tools, but also to ensure cutting the quality, while reducing the cost of the production process, improve production efficiency. Therefore, laser cutting technology is widely used in aviation manufacturing and other fields.

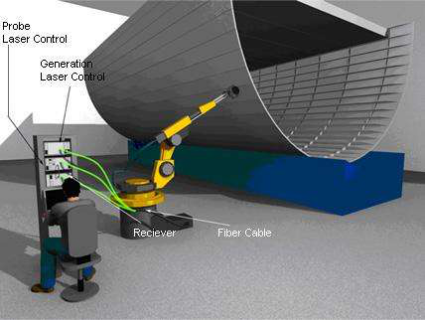

Laser welding

Aircraft manufacturing process used in laser welding of many places. Laser welding is widely used in the welding of thin-walled structures, the most typical aircraft structure is Aluminum Alloy European Airbus aircraft fuselage panel, the welding riveting structure will reduce the weight of the aircraft fuselage near 20%, reduce the manufacturing cost of about 20%, welding panel structure has been applied to the Airbus A318, A380 and A340 series aircraft the.

In the case of A380, the structure design of 6056/6013 laser welding with its fuselage panels, without stiffeners for connection and skin bending, reduce the structural weight of 5%-10%, but also reduce the cost of about 15%.

Using laser welding from the aircraft and reduce manufacturing cost, shorten production cycle, reduce the quality of the aircraft, or high performance aircraft has good performance. In addition, laser welding is also used for welding between fuselage panel, long truss and corner plate, such as laser welding, Al-Ti dissimilar materials, seat slide rail and so on.

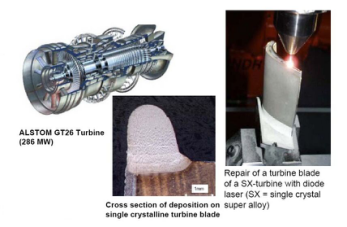

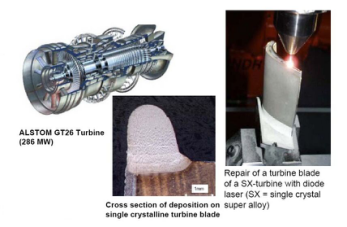

Laser cladding

Aviation industry was the first to draw on the advantages of laser cladding for the production department, because it can not only be used for processing parts, and can be used for repairing parts.

Laser cladding is an important method of surface modification technology of materials. It is the use of high energy laser beam on metal surface irradiated by melting, rapid expansion and rapid solidification, with special physical, chemical or mechanical properties on the substrate surface cladding a layer of materials so as to form a new composite material, in order to compensate for the high performance of the body lacks, the composite material can give full play to the two the advantage of the lack of make up for each other.

Contact wear of friction pairs of titanium alloy and nickel alloy in aero engine is a difficult problem in engine operation and maintenance,Laser cladding technology can obtain high quality coatings and create a new situation for the repair of gas turbine engine parts.

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam

中文

中文 English

English France

France العربية

العربية русский

русский español

español português

português srpski језик

srpski језик Việt Nam

Việt Nam